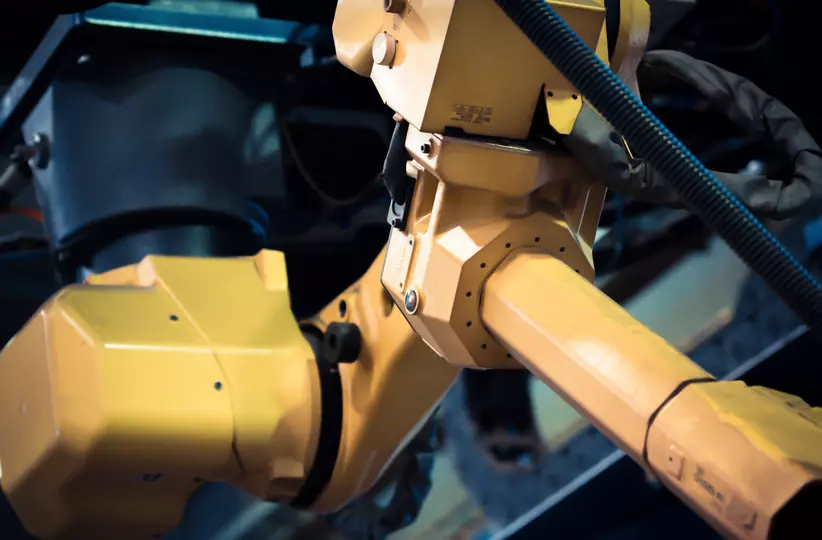

Securely Welded With the FANUC ARC Welding Robot

Get Inspired

Elevación de cargas pesadas para la construcción de camiones

NTM pudo aumentar la capacidad de producción de sus vehículos de recogida de basuras optando por automatizar el turno de noche. Gracias a un robot capaz de levantar hasta dos toneladas y a una solución de soldadura robotizada, la planta finlandesa de la empresa puede ahora trabajar sin personal por la noche o los fines de semana.

El Cobot CRX de FANUC aumenta la flexibilidad de la producción

Bonvicini Carpenteria disfruta hoy de niveles aún más altos de calidad y flexibilidad. La empresa puede alternar entre soluciones de automatización siempre que lo dicten los volúmenes de producción. En concreto, Bonvicini Carpenteria aprovecha las ventajas de una programación de robots fácil y rápida con funciones como arrastrar y soltar y una sencilla interfaz de tableta.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Soldadura por arco