Vision Inspection

Streamline your Vision Inspection with FANUC Robots

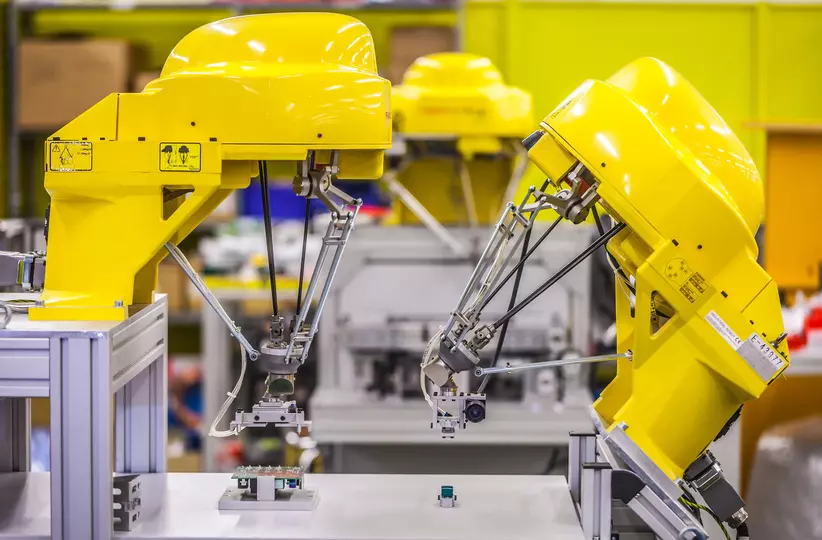

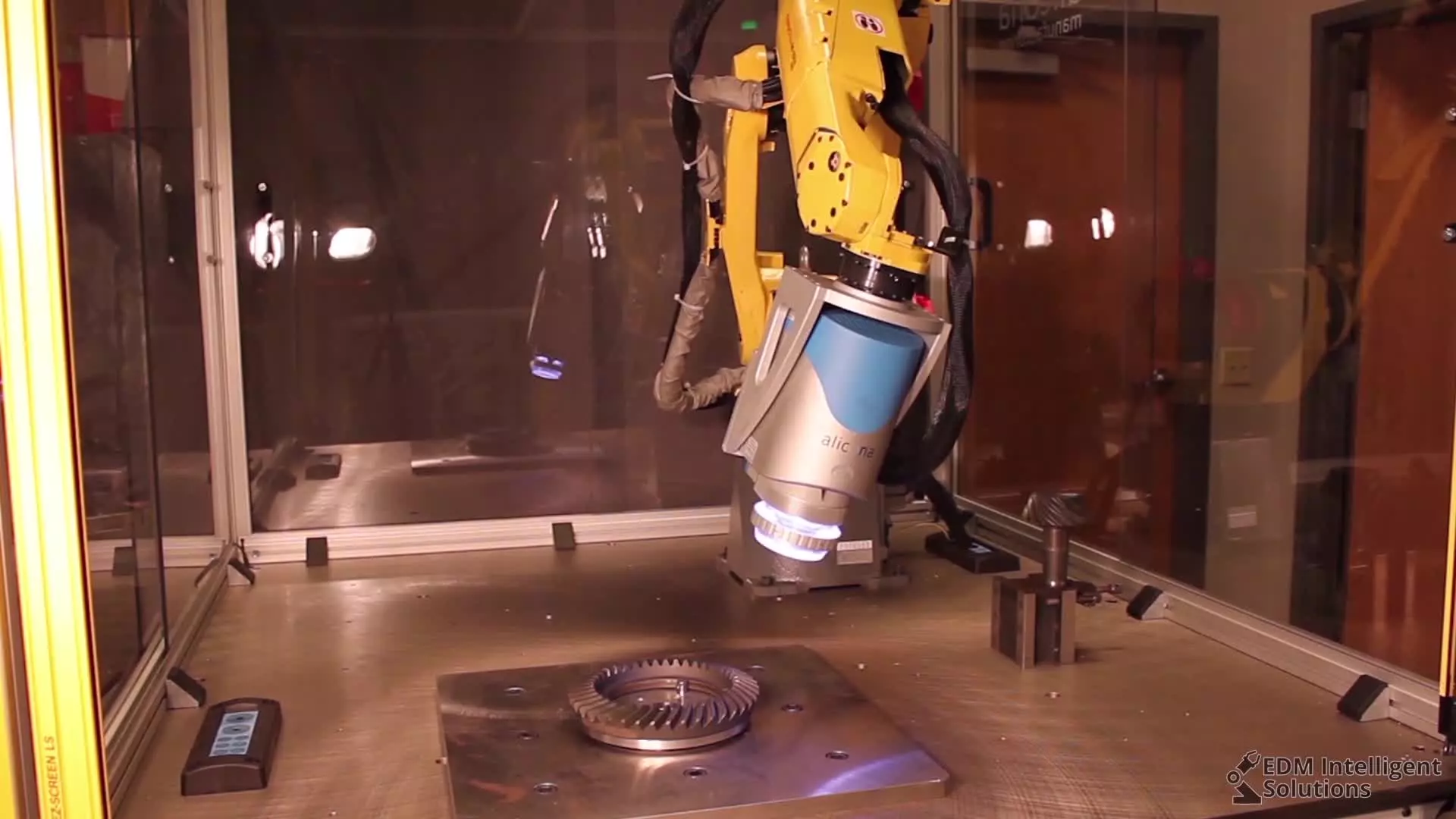

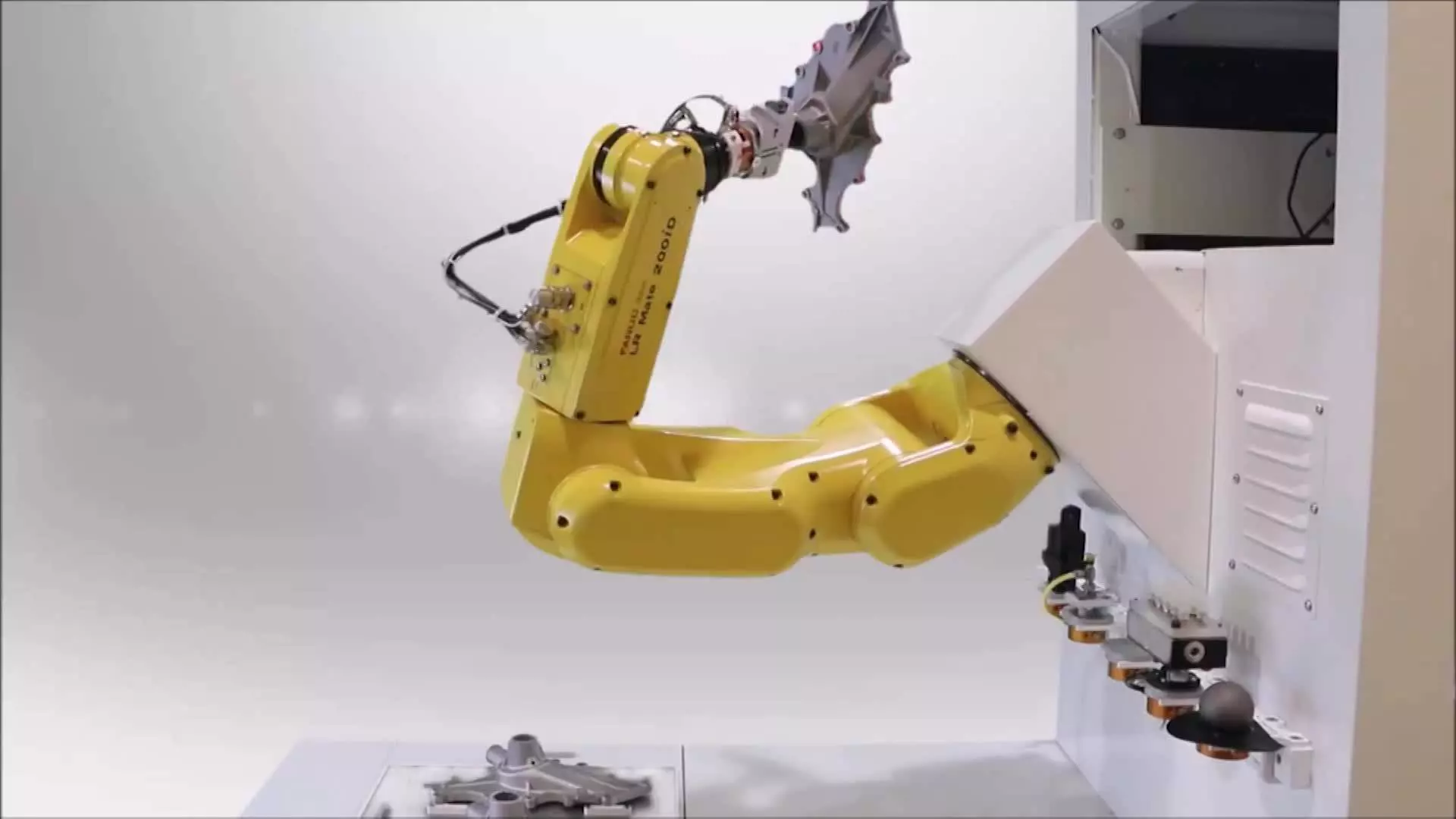

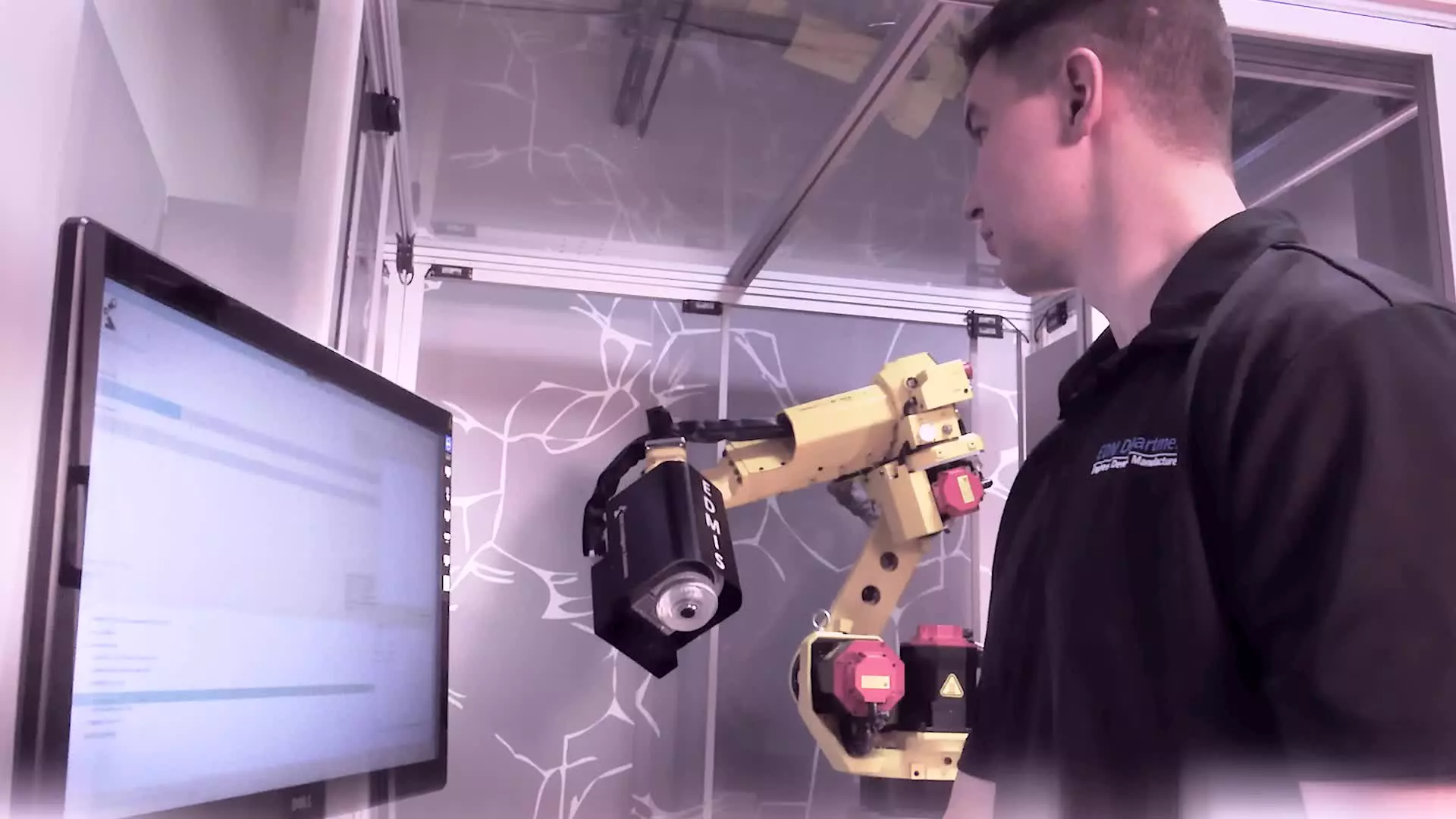

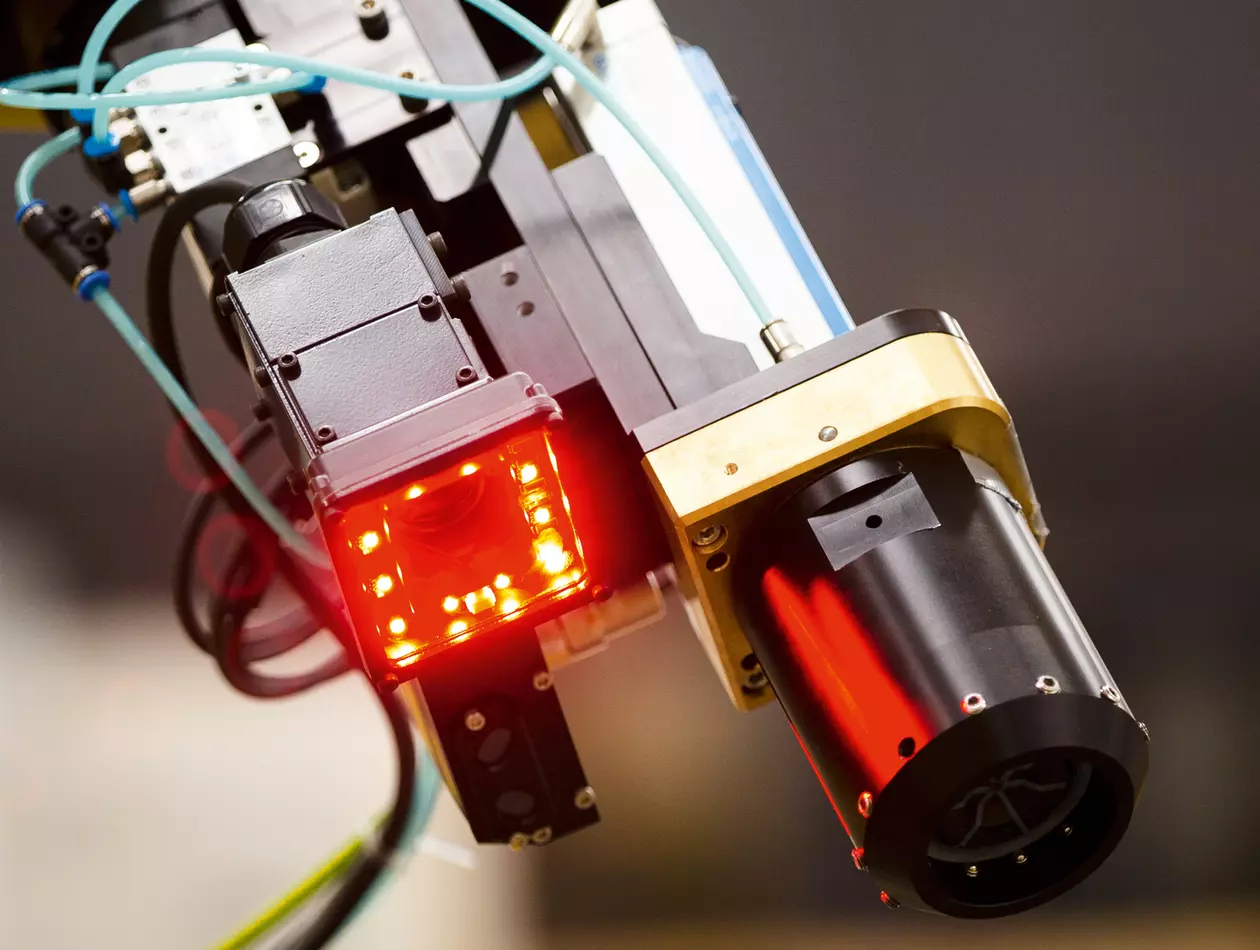

FANUC is a leading provider of industrial and robotic vision inspection systems, boasting decades of experience and expertise. Renowned in the industry, FANUC is one of the few suppliers of industrial robots and cobots that seamlessly integrates its proprietary vision system with its robots — every robot comes "𝑖RVision Ready". This means our robots are ready to enhance your processes, making them faster, more efficient, and more profitable for your business.

Additionally, the 𝑖RVision 2D provides fast and reliable visual recognition, making it ideal for identifying and aligning parts accurately. The 𝑖RVision 3D takes it a step further by adding depth perception, which allows for handling complex objects and pinpointing locations in 3D space. These systems work seamlessly with our robots, boosting automation efficiency and ensuring top-notch inspection quality.

Get Inspired

Get Inspiration from Other's Success

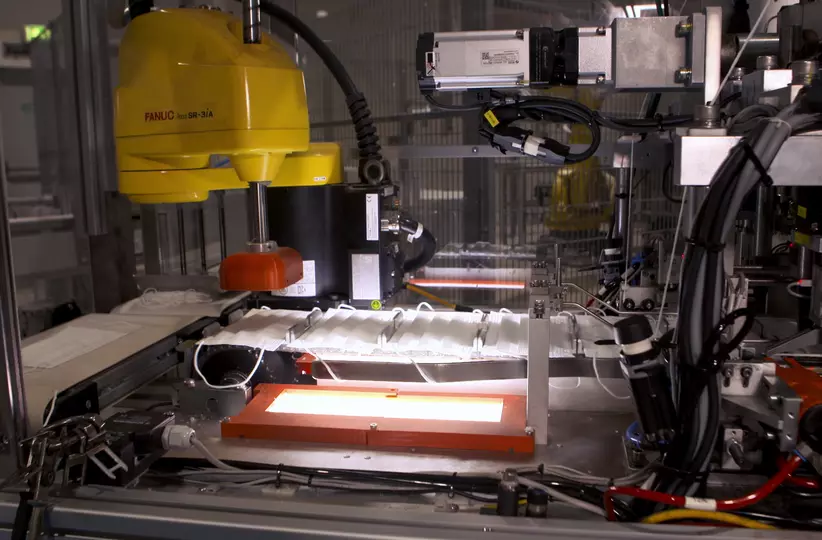

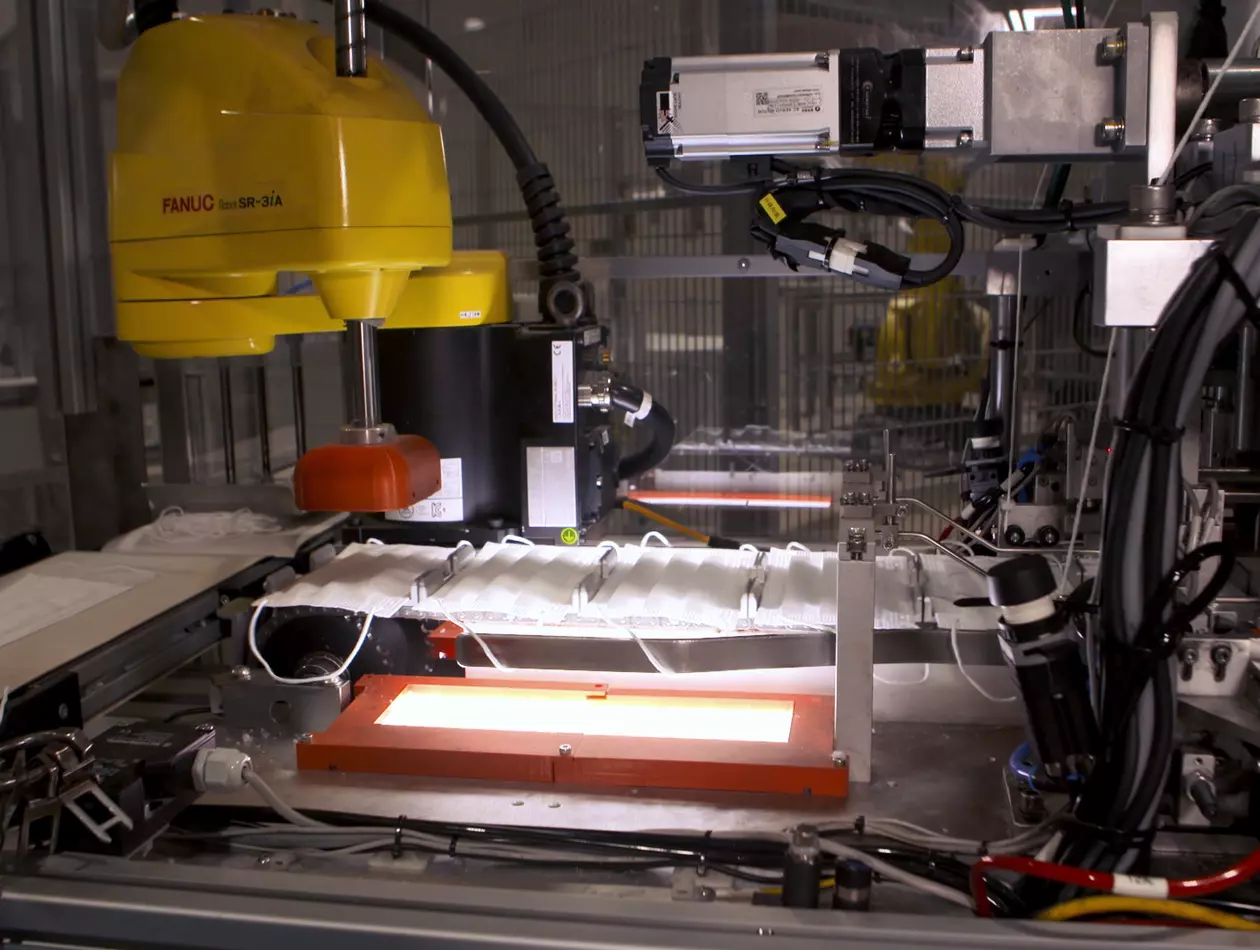

FANUC Robots Help Mask Producer Face up to the Challenge

When production demand accelerates dramatically in a short space of time, robots and automation can help meet requirements much faster than many realise. However, this outcome depends heavily on the selection of robots that are easy to install, program and commission.

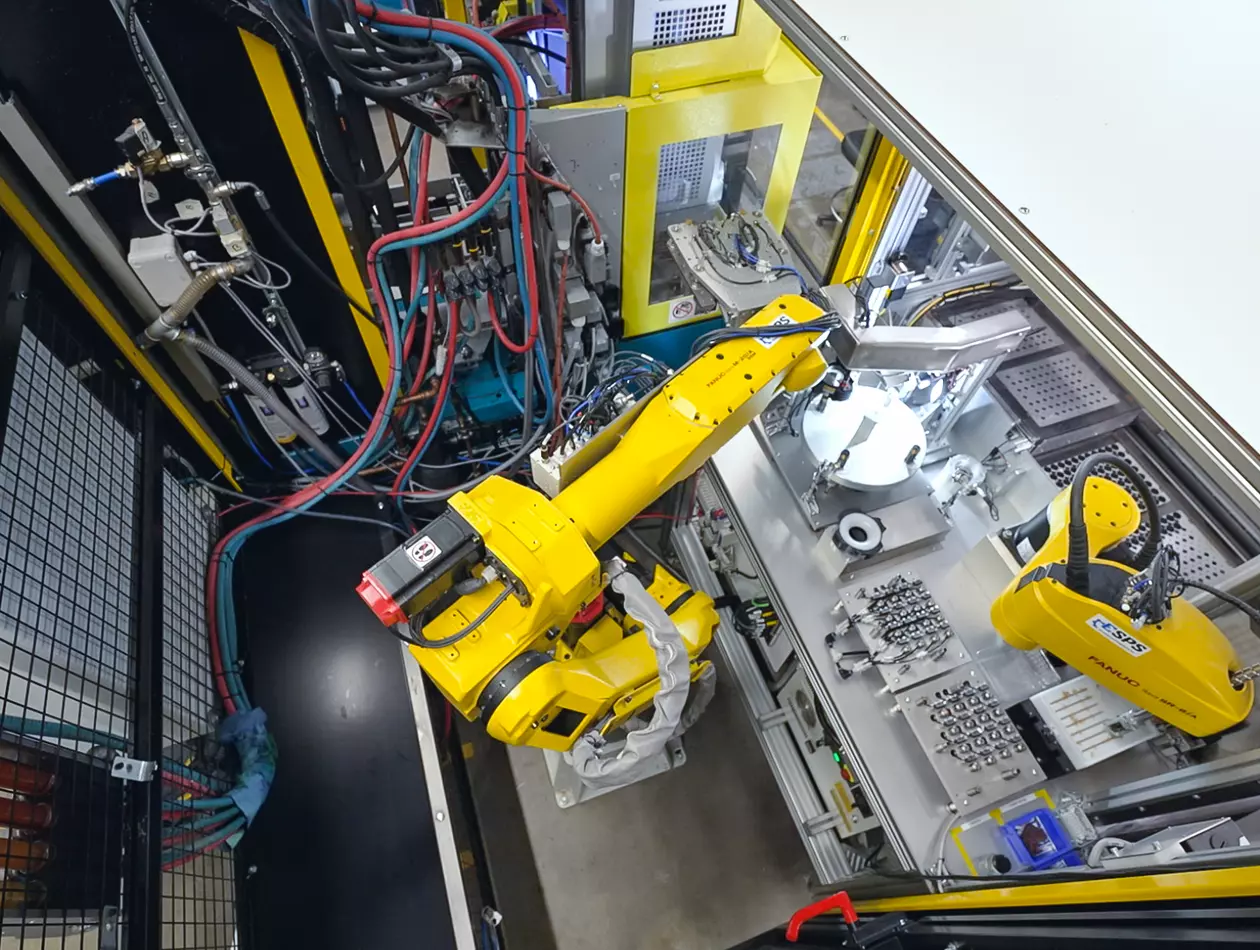

Loading & Unloading, Flex Feeding, and Inspection in a Single Cell

Vernay is globally renowned for flow control solutions, producing over a billion rubber valve components annually across Asia, the Americas, and Europe. Their critical products, used in devices like respirators and EV battery systems, must meet the highest quality standards with zero defects.

Industry Applications for FANUC Vision Inspection

Automotive

Electric Vehicles

Electronics

Food and Beverage

Warehousing

All Industries

Learn More about our Vision Inspection Possibilities

Our Solutions for Other Applications

Boost Efficiency, Precision, and Productivity with FANUC's Solutions for Different Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.