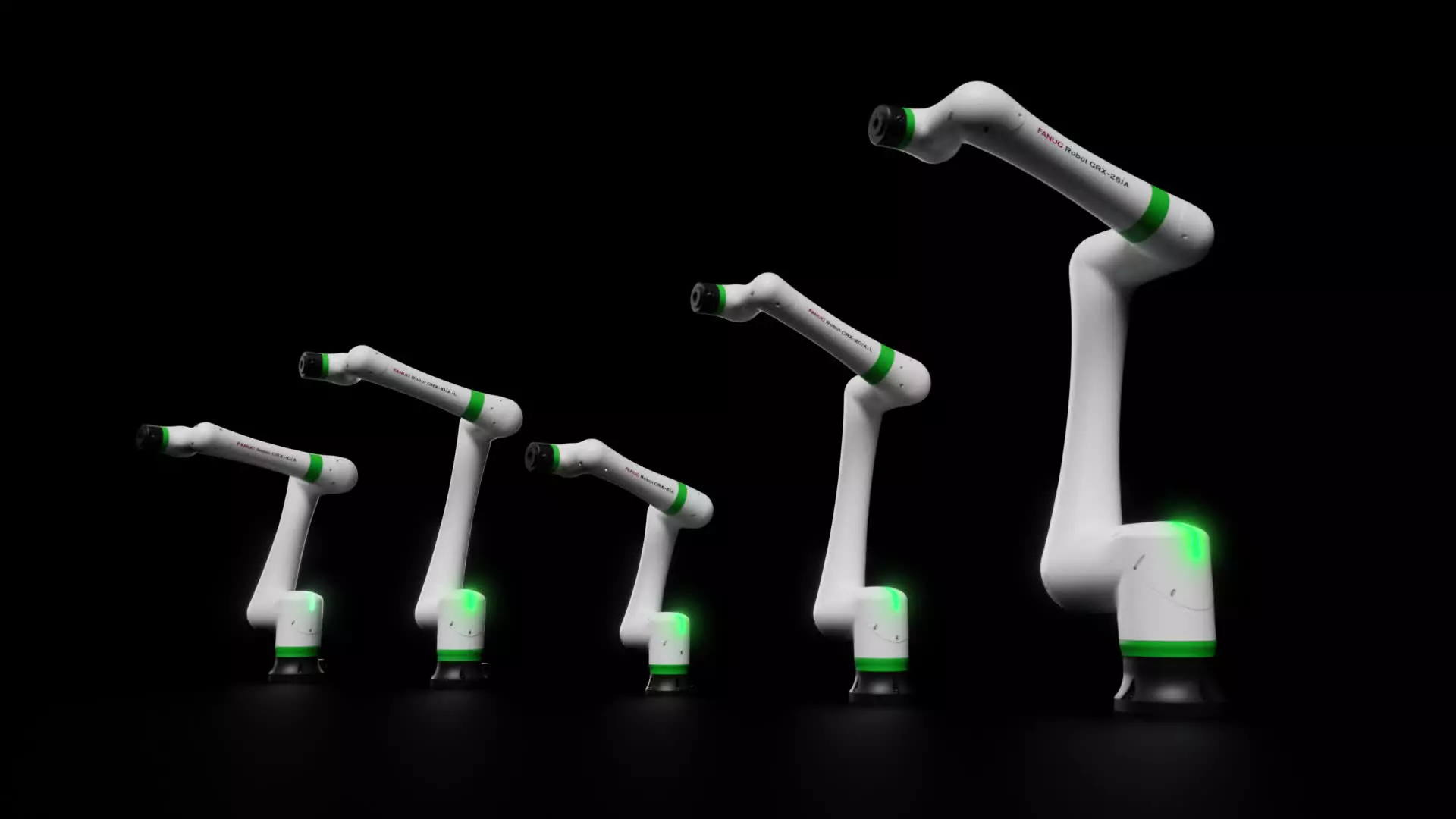

FANUC Collaborative Robots

Where There're Industrial Cobots, There's FANUC

When you need an industrial cobot, look no further than FANUC. As the world’s leading cobot manufacturer, we offer a variety of high-precision cobot models able to handle products that weigh up to 50 kg. Whether you’re experienced with traditional industrial robots, or have yet to work with a robot arm, we have a cobot solution to work in your production environment. After 50 years in the robotics business, we understand today’s production environments, from small batch/high-mix runs to large batch/low-mix runs. So, when the time is right to consider a collaborative robot application, you can rely on FANUC to help you understand the most efficient and cost-effective solution.

Get Inspired

Get Inspiration from Other's Success

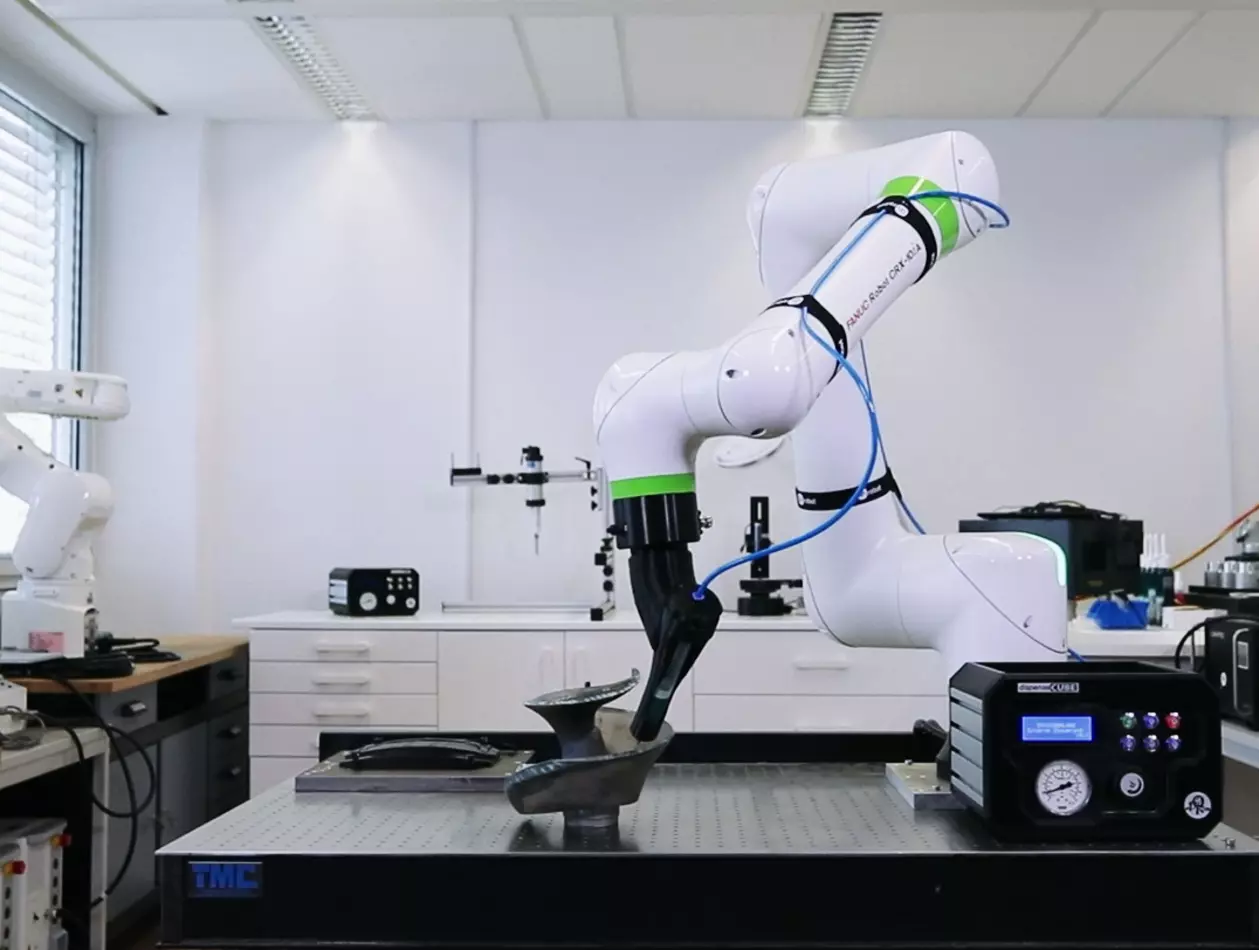

Joining Forces: FANUC Cobot is Optimal Solution for AS Adhesive Solutions

Automation is not just for high-volume applications. AS Adhesive Solutions, a specialist consultant and partner for the adhesives industry, recognises that many SMEs processing small quantities can benefit from full or part-automated processes. In such instances, a collaborative robot (cobot) often provides the optimal way forward.

Cobot Relieves Workers of Physical Strain

Quality checks and packaging can be physically demanding. However, the integration of collaborative robots can significantly enhance the ergonomics of such activities.

FANUC Cobot Helps GER4TECH Make its Move

Developing a new robot requires expertise, experience and often collaboration with partners who have specialised knowledge in specific technology fields. So, when GER4TECH wanted a specialist in collaborative robots to bring advanced capabilities to its new autonomous mobile robot (AMR), the company reached out to FANUC.

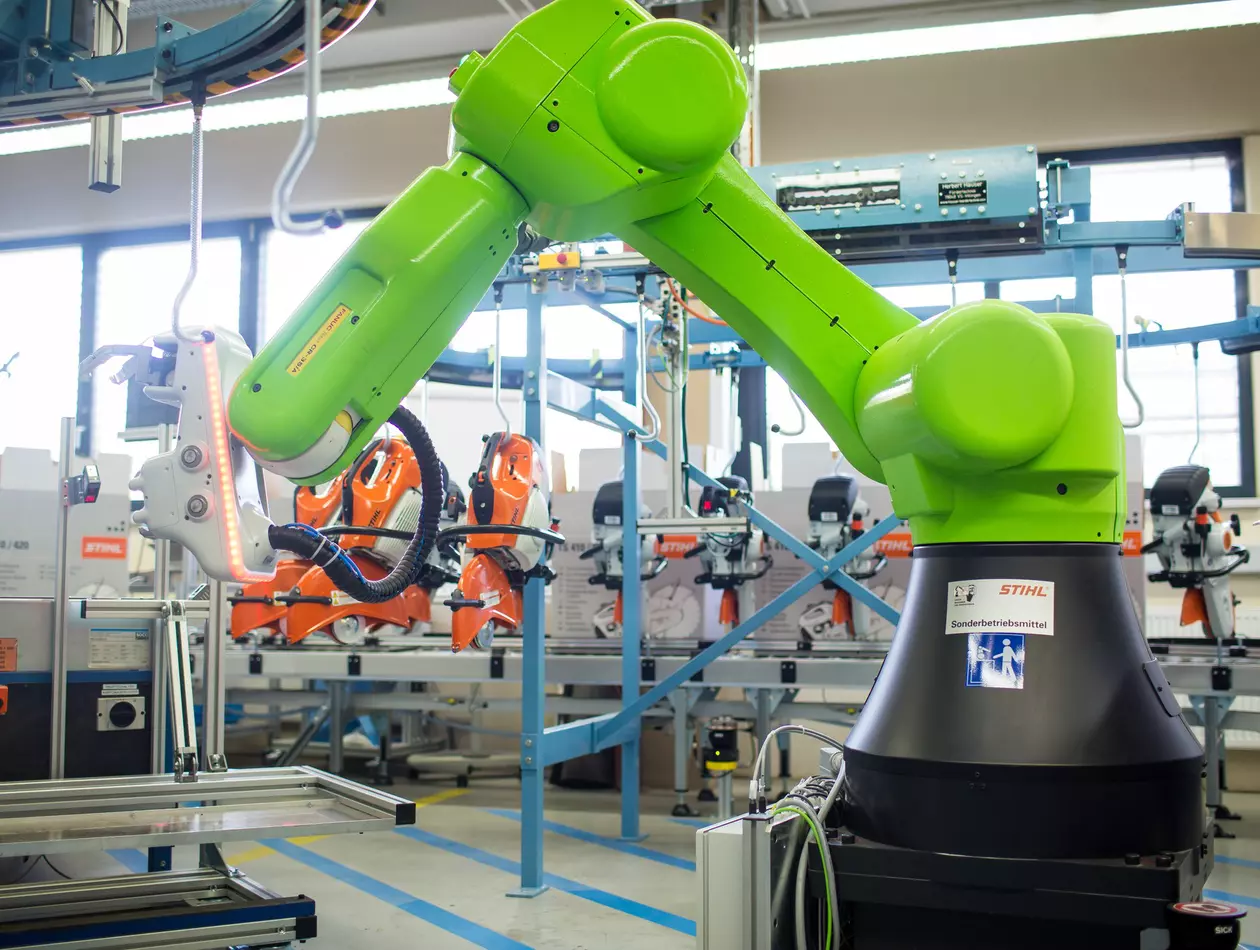

FANUC's CRX Cobot Boosts Production Flexibility

Bonvicini Carpenteria today enjoys even higher levels of quality and flexibility. The company can flex between automation solutions whenever production volumes dictate. In particular, Bonvicini Carpenteria is taking advantage of easy and fast robot programming with features such as drag and drop functionality and a simple tablet interface.

Perfect Fit for Your Application

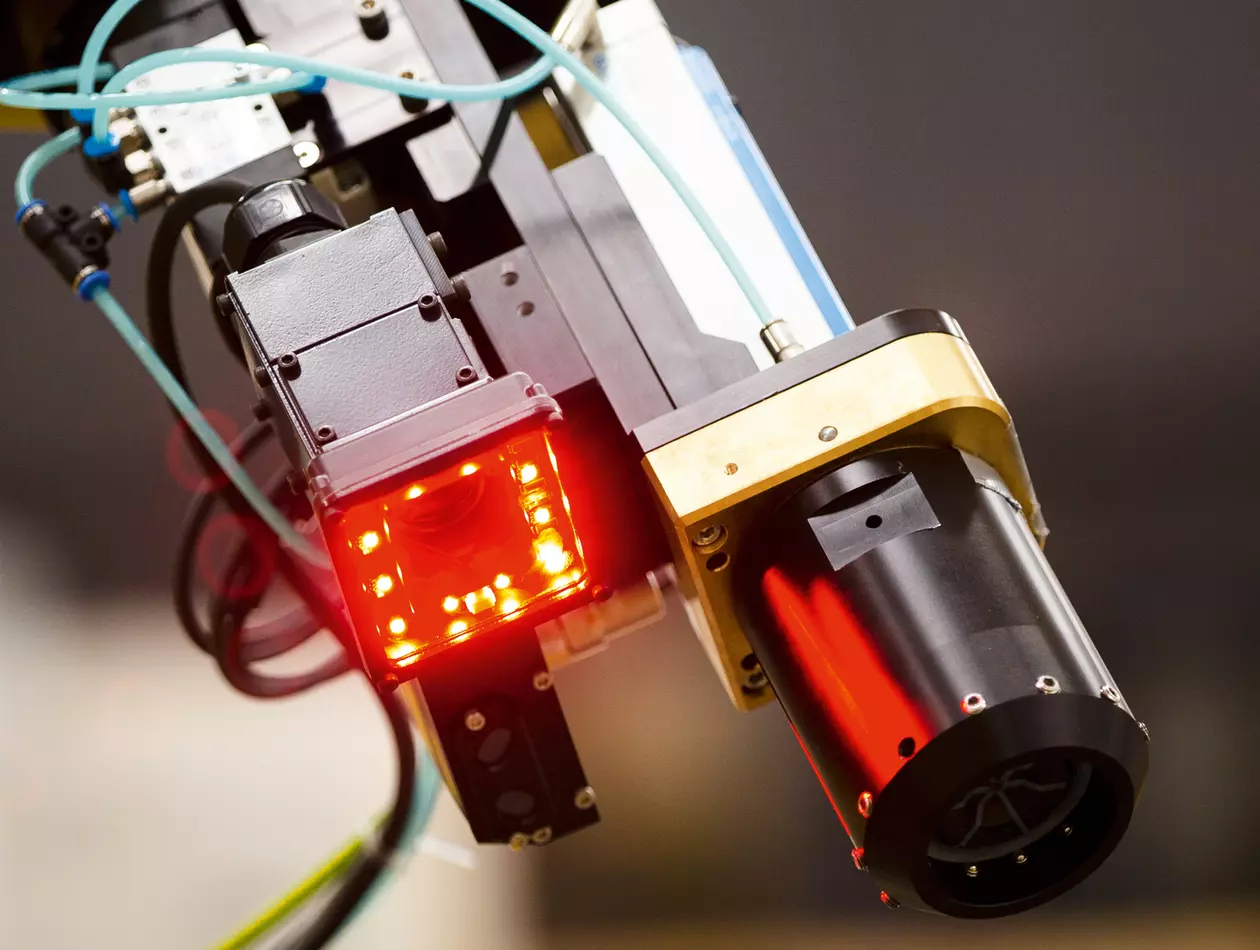

Arc Welding

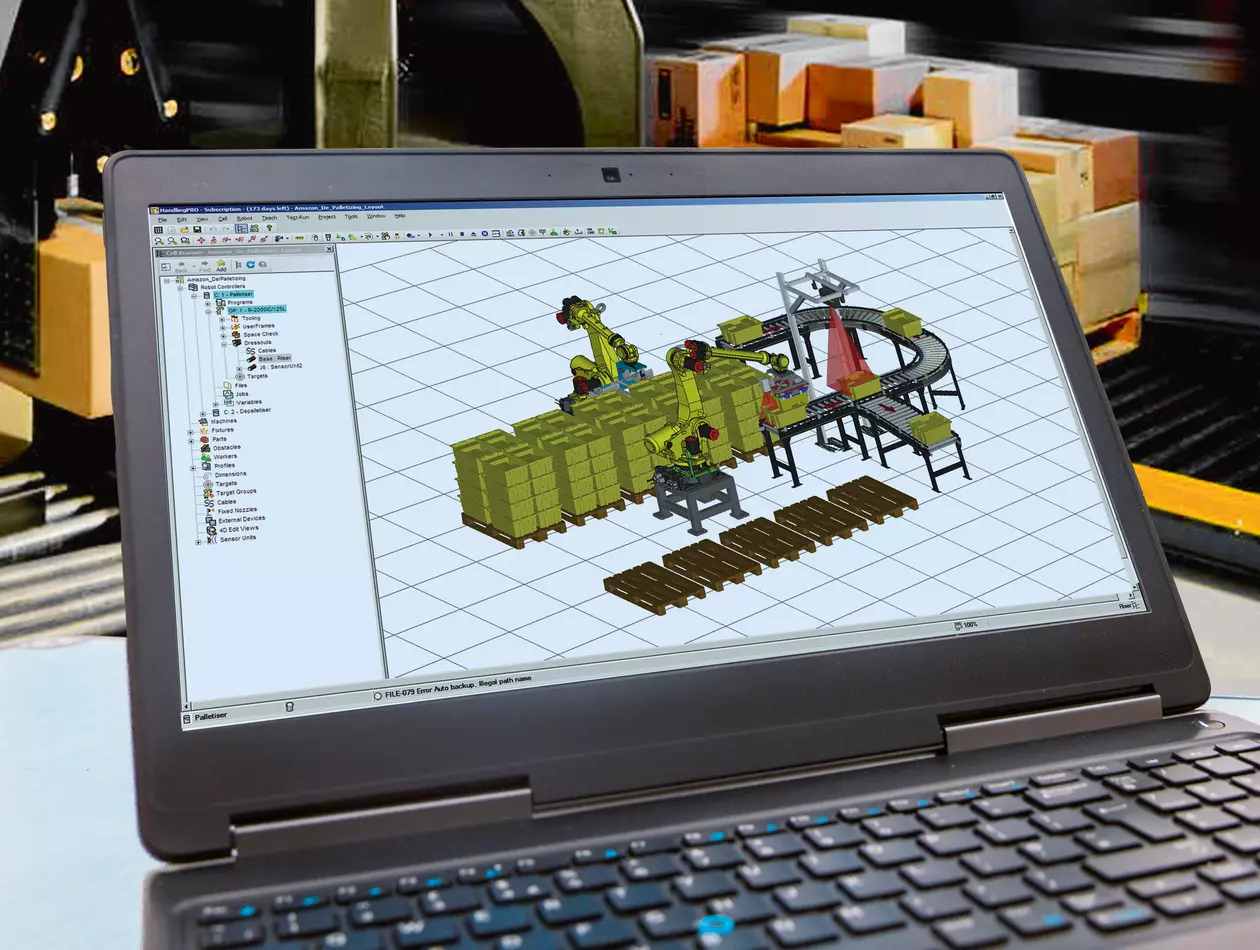

Palletising

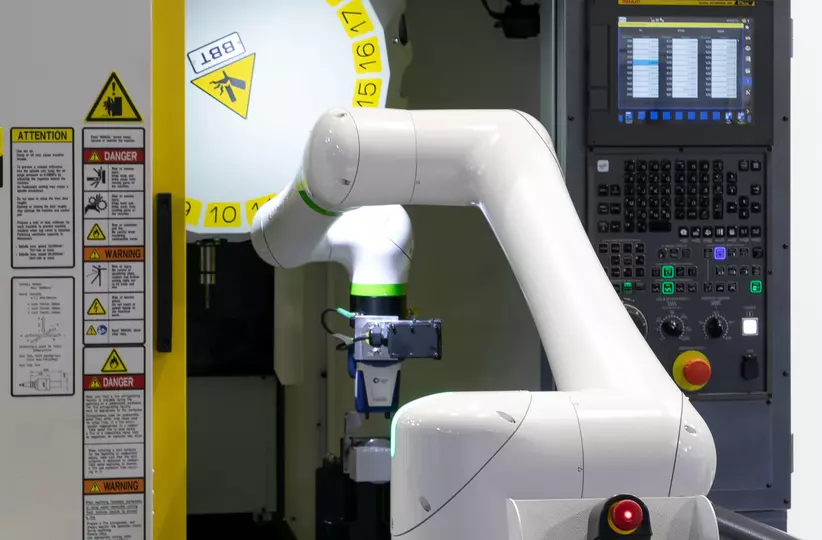

Machine Tending

Vision Inspection

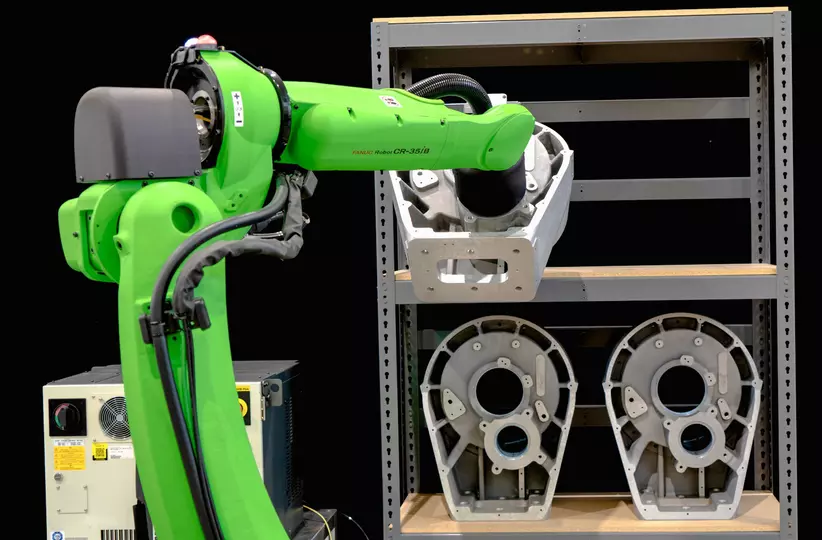

Material Handling

Assembling

Tailored Solutions for Your Industry

Robotics & Automation for the Automotive Industry

Robotics & Automation for the Aerospace Industry

Electric Vehicles

Food & Beverage

Electronics