“In our latest project for an international manufacturer of clamping tools operating in the electrical industry, we were tasked with creating a fully automatedproduction

“In our latest project for an international manufacturer of clamping tools operating in the electrical industry, we were tasked with creating a fully automatedproduction

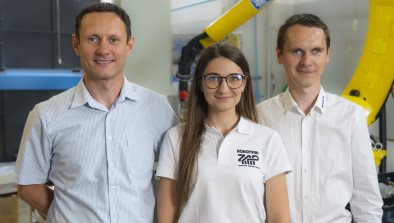

line that would ensure a constant, defined cycle time for machining the clamping tool forgings,” explains Krystian Młynarczyk, Technologist at ZAP-Mechanika.ZAP-Mechanika subsequently engaged the services of sister company ZAP-Robotyka, an experienced specialist in the development and integration of robotic and automated workstations. Also based in Ostrów Wielkopolski, ZAP-Robotyka accepted the challenge, designing, constructing, delivering and implementing the entire production cell on behalf of ZAP-Mechanika.

Paweł Wróbel, Project Specialist at ZAP-Robotyka, explains the design and configuration: “In the robotic cell there’s a FANUC M-20iD/35 six-axis industrial robot equipped with two FANUC iRVision 3D vision systems. The vision-enabled robot serves two ROBODRILL CNC machining centres [α-D21LiA5 and α-D21LiB5 models]. Each iRVision system connects directly to the robot, so ZAP-Mechanika can take advantage of extremely fast communication.”

Thanks to the large field of view, FANUC iRVision systems are able to recognise and pick up randomly positioned objects straight from a workpiece tote bin as large as a pallet. The robot subsequently loads and unloads parts to and from the ROBODRILL machines. But that is not all, there is an extra innovation in the cell designed by ZAP-Robotyka.

Thanks to the large field of view, FANUC iRVision systems are able to recognise and pick up randomly positioned objects straight from a workpiece tote bin as large as a pallet. The robot subsequently loads and unloads parts to and from the ROBODRILL machines. But that is not all, there is an extra innovation in the cell designed by ZAP-Robotyka.

“The system allows ZAP-Mechanika to work autonomously,” reveals Marta Portasiak, Constructor at ZAP-Robotyka. “This non-standard approach makes it possible to produce two different components in a single cell, with a single robot, significantly accelerating the production process.”

The project also saw ZAP-Robotyka develop a novel system for gripping and manipulating parts, and design special tooling for the workstation.

“The application has increased our productivity with fewer resources, while making our work easier and delivering continuity across the process,” says Tomasz Krazynski, CEO at ZAP-Mechanika.

A traditional set-up to machine the clamping tool forgings would require three machine tools and three operators. In contrast, ZAP-Mechanika is using only one operator, one FANUC robot, two FANUC machine tools and two FANUC 3D cameras.

“This cell clearly sets out our goals for the future,” concludes Krazynski. “We’ll continue to invest in automation moving forward and keep developing robotic production cells.”