Erkul Cosmetics

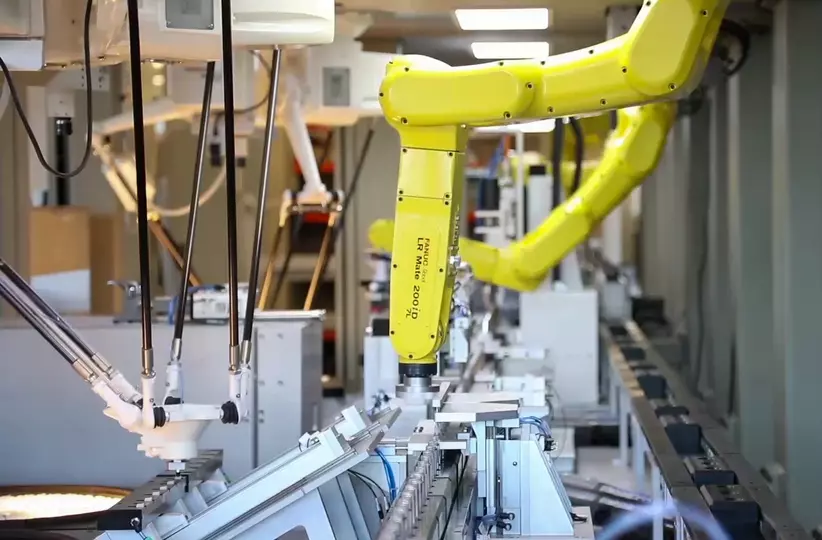

Cosmetics Manufacturer Sees the Beauty of FANUC Automation

Erkul Cosmetics in Turkey benefits from a myriad of quality and efficiency benefits provided by various high-performance FANUC automation products. This fast-growing cosmetics enterprise is looking to set a benchmark for manufacturing in its sector, supported by the competitive gains that FANUC solutions provide.

Share

The combination of FANUC’s all-electric injection moulding machines and robots drives continuous improvement.

FANUC’s product reliability results in uninterrupted production, low maintenance costs and rapid ROI.

Industry 4.0 technologies from FANUC offer remote access capabilities.

Energy savings of around 70%.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Injection Moulding

Injection moulding is a highly efficient manufacturing process that enables the production of complex, high-quality plastic components with precision and consistency. Utilising advanced automation and robotics, this technology is essential for industries requiring large-scale production, ensuring cost-effective solutions without compromising on the integrity or performance of the final product.

Material Handling

Automise material handling with industrial robots to unlock numerous advantages for your business. Significantly enhance efficiency and productivity by reducing the time and effort required for manual handling. Let robots operate continuously without fatigue to ensure consistent performance and minimise errors, leading to higher throughput and faster processing times.

All Industries

Explore our comprehensive range of factory automation solutions, designed to optimise and streamline any manufacturing process.