AKE

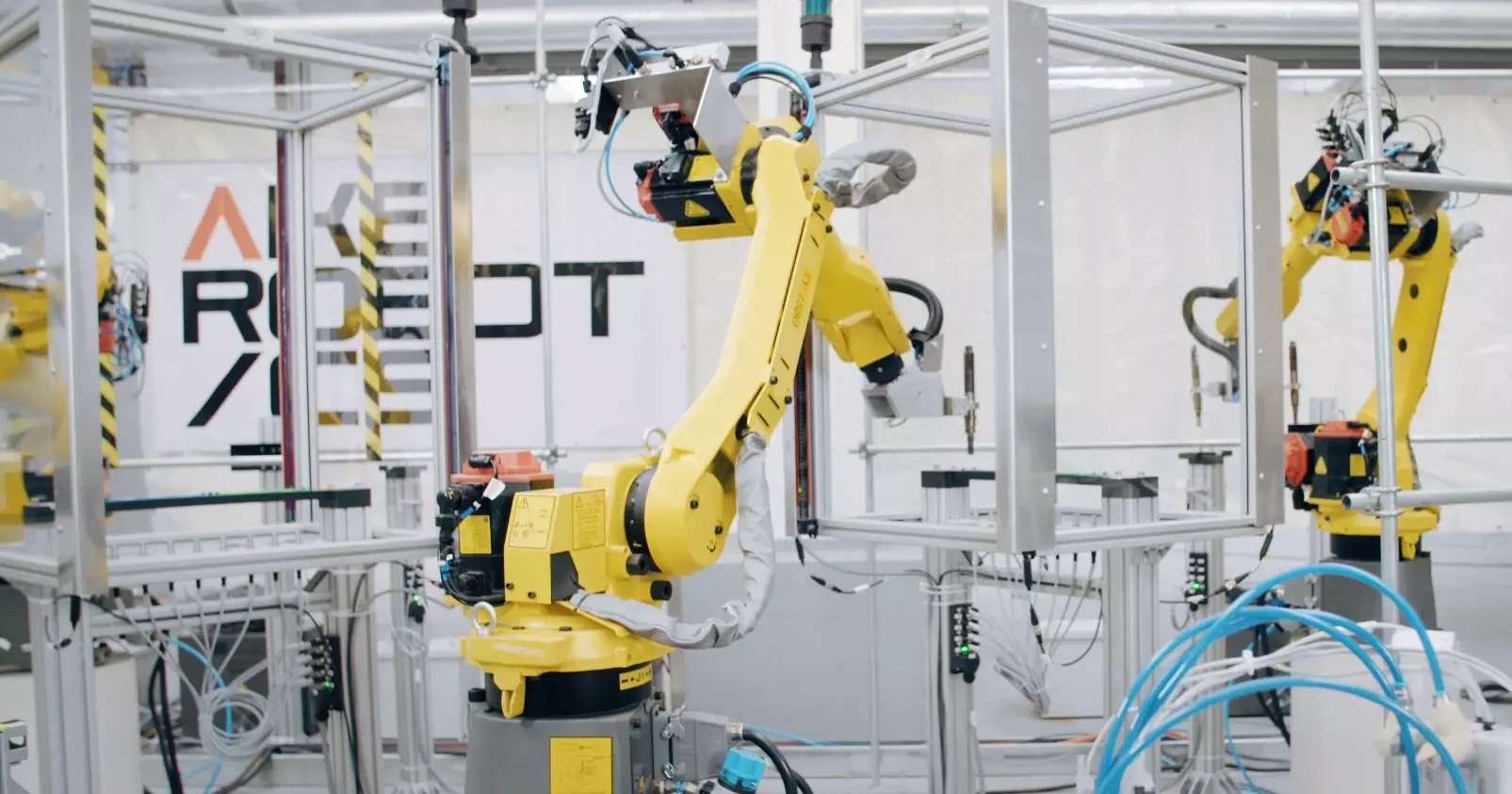

AKE Deploys FANUC Robots to Steer Success at Nexteer

Nexteer Automotive is taking advantage of nine high-performance industrial robots from FANUC to automate the manufacturing of steering gear components required for BMW. Installed by process automation specialist AKE Robotics, the plant is seeing new levels of process productivity and reliability.

Share

Higher productivity with ultra-short cycle time of just 16 seconds.

Better flow of process materials.

No more skills issues due to lack of qualified workers.

Redeployment of operators to more added-value tasks.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Material Handling

Automise material handling with industrial robots to unlock numerous advantages for your business. Significantly enhance efficiency and productivity by reducing the time and effort required for manual handling. Let robots operate continuously without fatigue to ensure consistent performance and minimise errors, leading to higher throughput and faster processing times.

Robotics & Automation for the Automotive Industry

Automotive excellence: FANUC's versatile automation solutions.