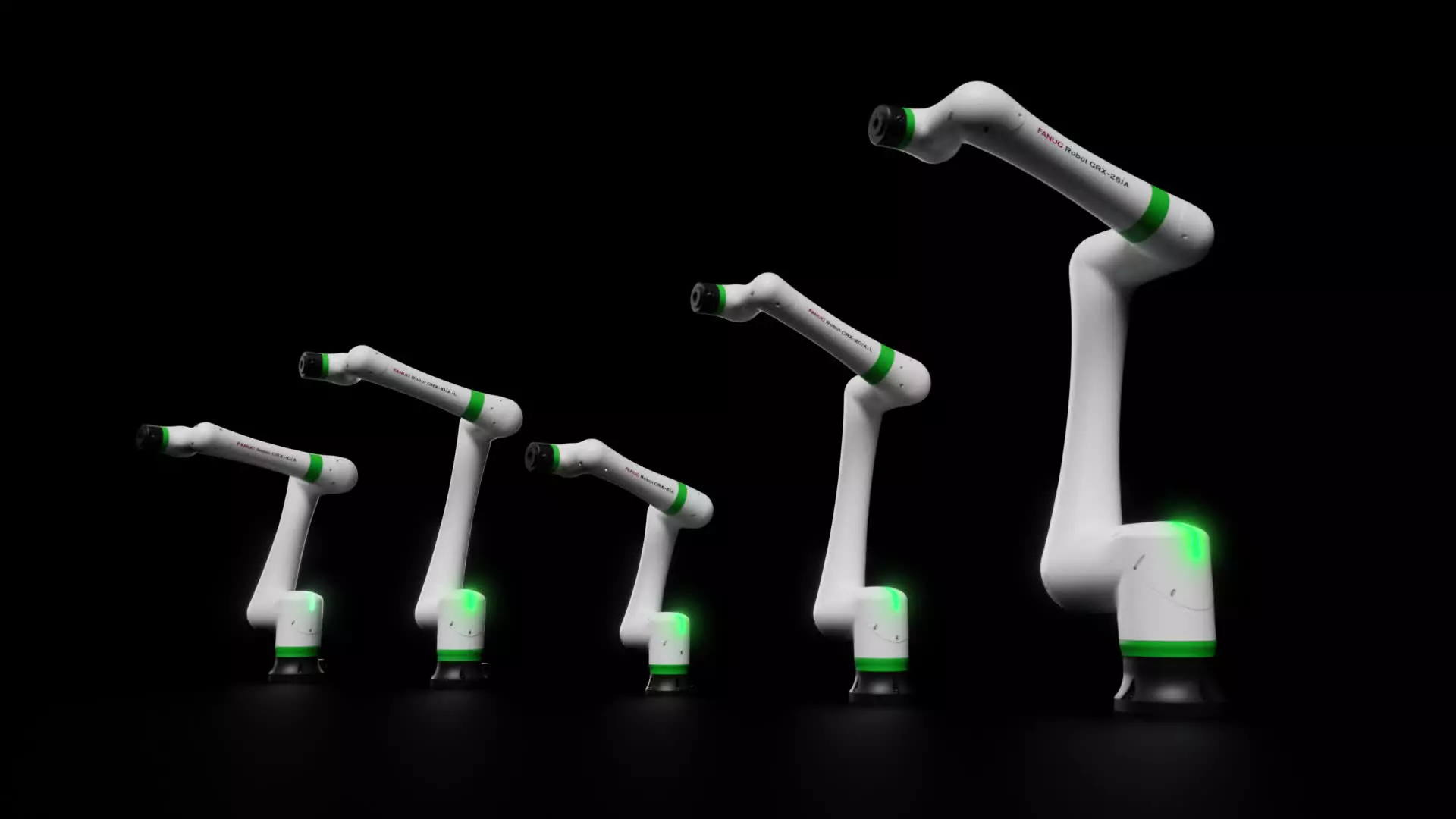

Robots collaboratifs FANUC

Là où il y a des cobots industriels, il y a FANUC

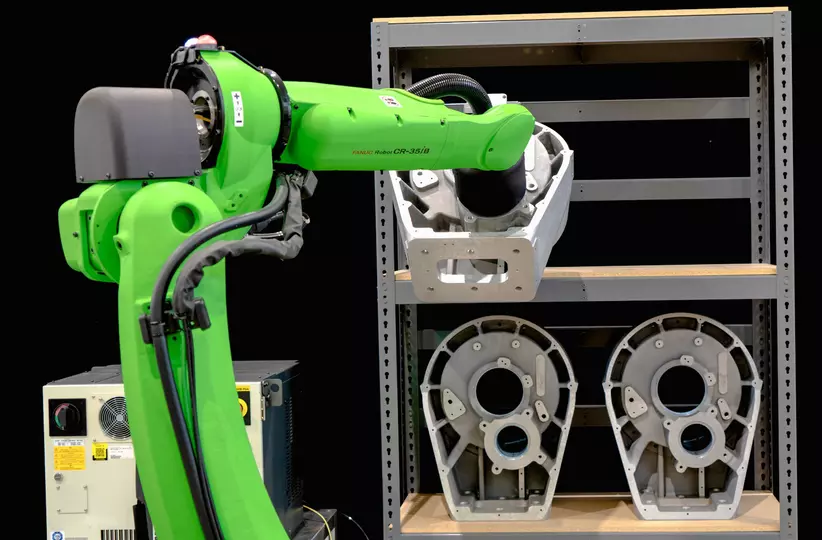

Lorsque vous avez besoin d'un cobot industriel, ne cherchez pas plus loin que FANUC. En tant que premier fabricant mondial de cobots, nous proposons une variété de modèles de cobots de haute précision capables de manipuler des produits pesant jusqu'à 50 kg. Que vous ayez de l'expérience avec les robots industriels traditionnels ou que vous n'ayez pas encore travaillé avec un bras robotisé, nous avons une solution cobot adaptée à votre environnement de production. Après 50 ans d'activité dans le secteur de la robotique, nous comprenons les environnements de production d'aujourd'hui, qu'il s'agisse de petites séries et de mélanges élevés ou de grandes séries et de mélanges faibles. Ainsi, lorsque le moment est venu d'envisager une application de robot collaboratif, vous pouvez compter sur FANUC pour vous aider à comprendre la solution la plus efficace et la plus rentable.

S'inspirer

S'inspirer de la réussite des autres

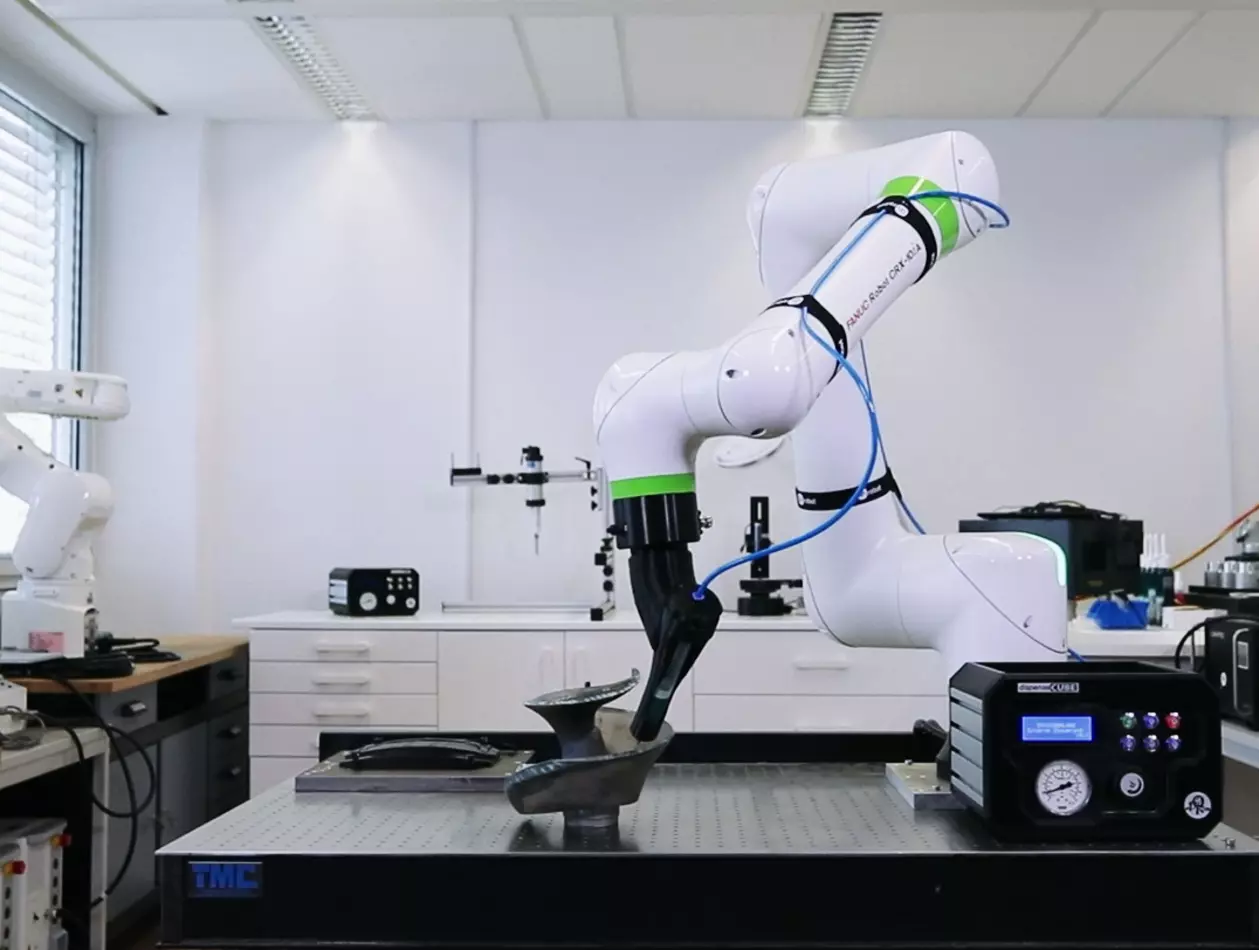

Unir nos forces : Le cobot FANUC est la solution optimale pour les solutions adhésives AS

L'automatisation n'est pas réservée aux applications à haut volume. AS Adhesive Solutions, consultant spécialisé et partenaire de l'industrie des adhésifs, reconnaît que de nombreuses PME traitant de petites quantités peuvent bénéficier de processus entièrement ou partiellement automatisés. Dans de tels cas, un robot collaboratif (cobot) constitue souvent la solution optimale.

Le cobot soulage les travailleurs des contraintes physiques

Les contrôles de qualité et l'emballage peuvent être physiquement éprouvants. Cependant, l'intégration de robots collaboratifs peut considérablement améliorer l'ergonomie de ces activités.

FANUC Cobot Helps GER4TECH Make its Move

Developing a new robot requires expertise, experience and often collaboration with partners who have specialised knowledge in specific technology fields. So, when GER4TECH wanted a specialist in collaborative robots to bring advanced capabilities to its new autonomous mobile robot (AMR), the company reached out to FANUC.

Le cobot CRX de FANUC améliore la flexibilité de la production

Bonvicini Carpenteria bénéficie aujourd'hui de niveaux de qualité et de flexibilité encore plus élevés. L'entreprise peut varier entre les solutions d'automatisation chaque fois que les volumes de production l'exigent. Bonvicini Carpenteria profite notamment d'une programmation facile et rapide des robots grâce à des fonctionnalités telles que le glisser-déposer et une interface simple sur tablette.

Une adaptation parfaite à votre application

Soudage à l'arc

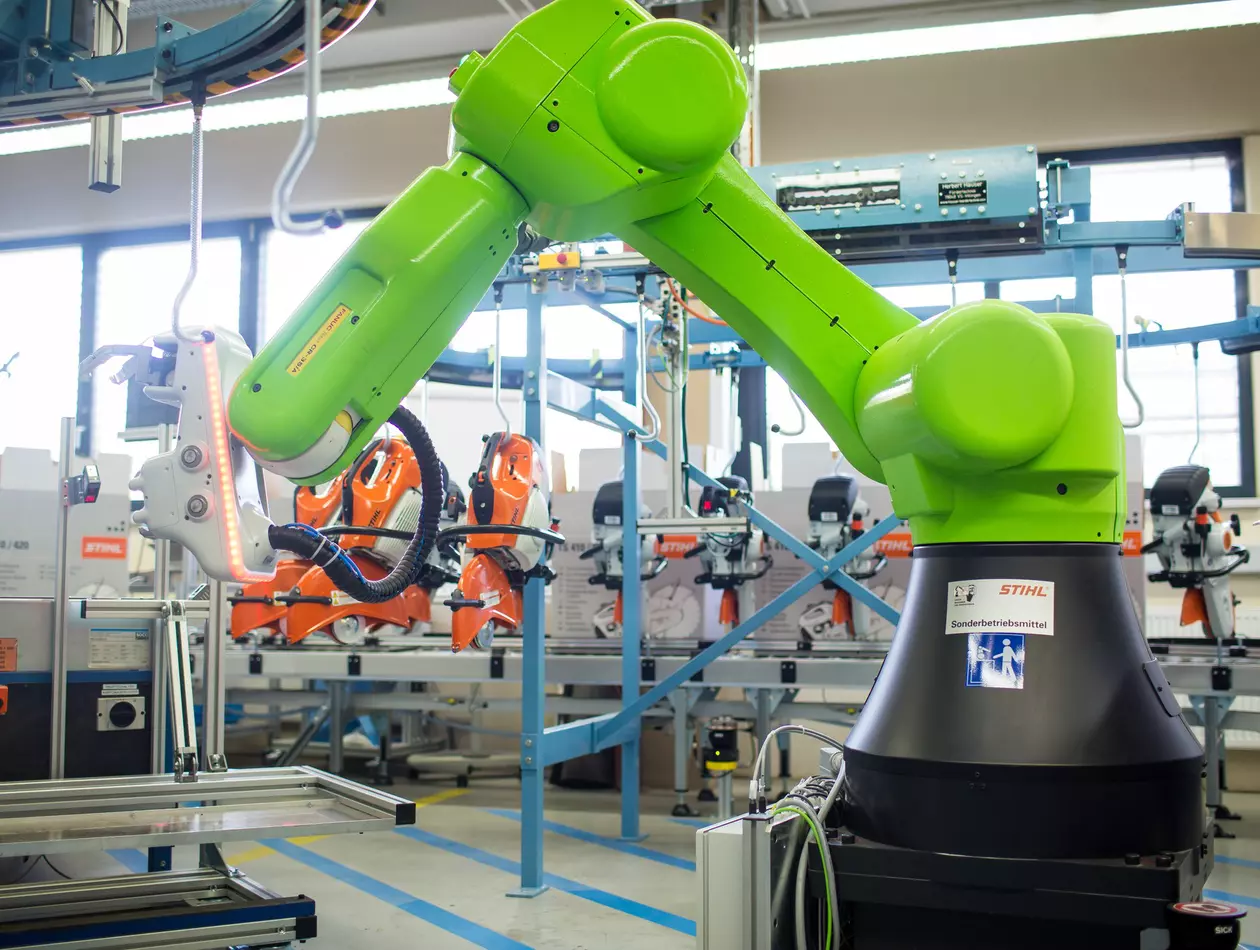

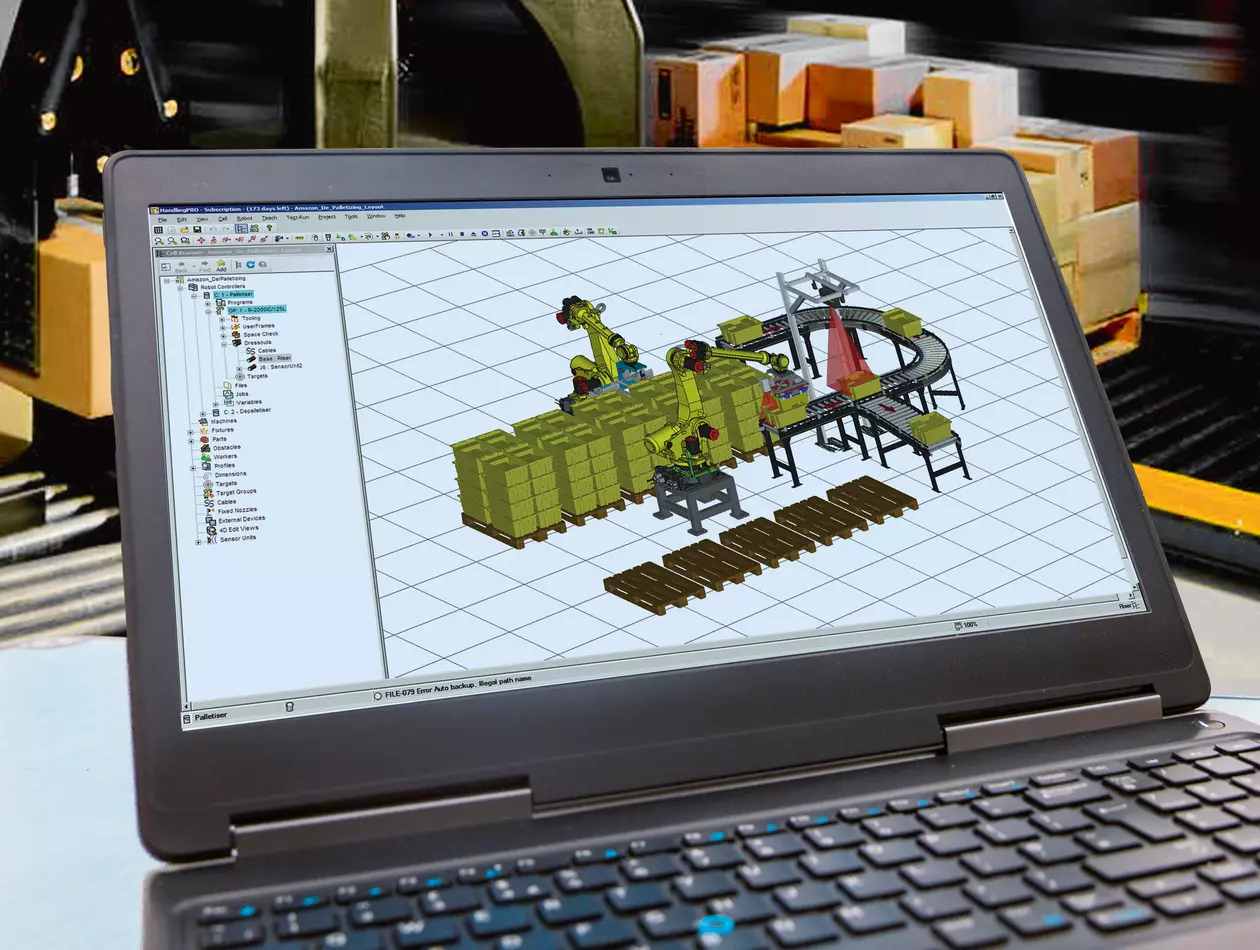

Palettisation

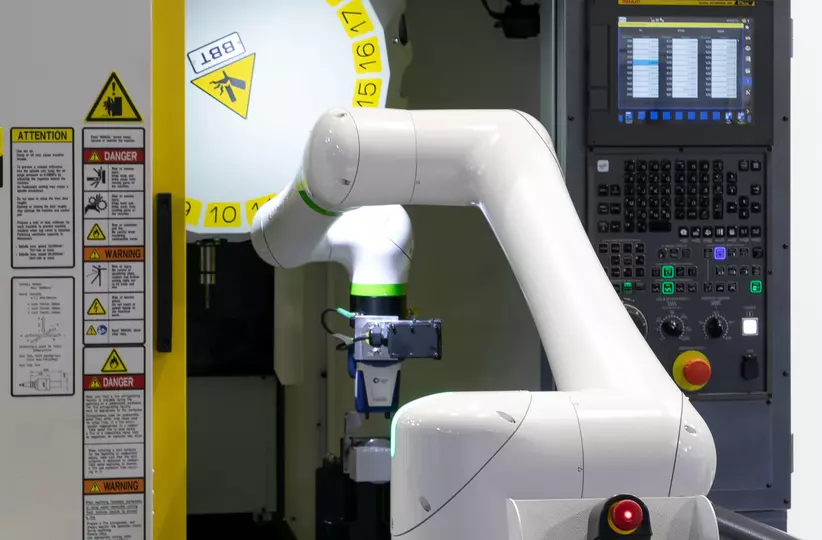

Entretien des machines

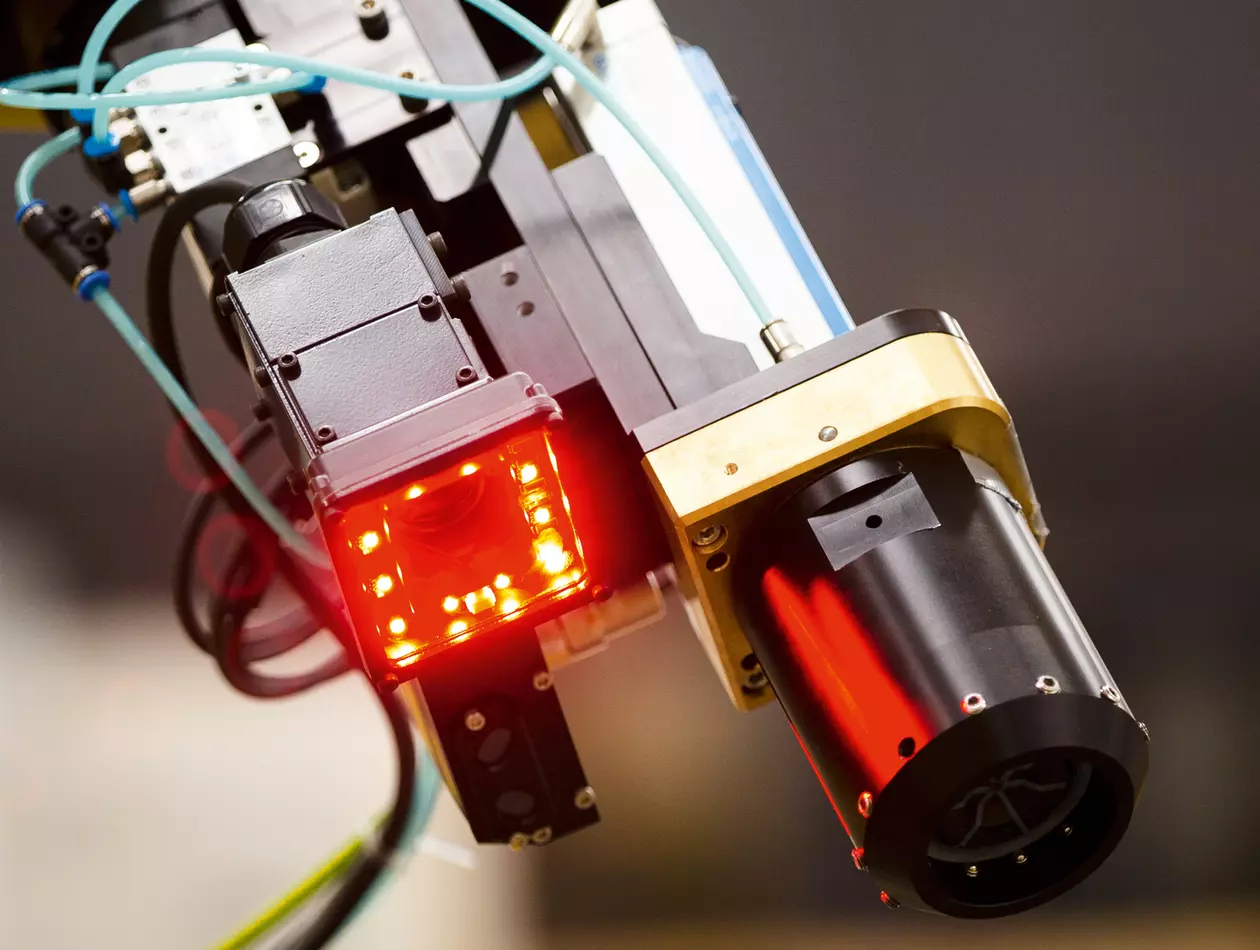

Inspection de la vision

Manutention

Assemblage

Des solutions sur mesure pour votre secteur d'activité

Robotique et automatisation pour l'industrie automobile

Robotique et automatisation pour l'industrie aérospatiale

Véhicules électriques

Agroalimentaire

Électronique