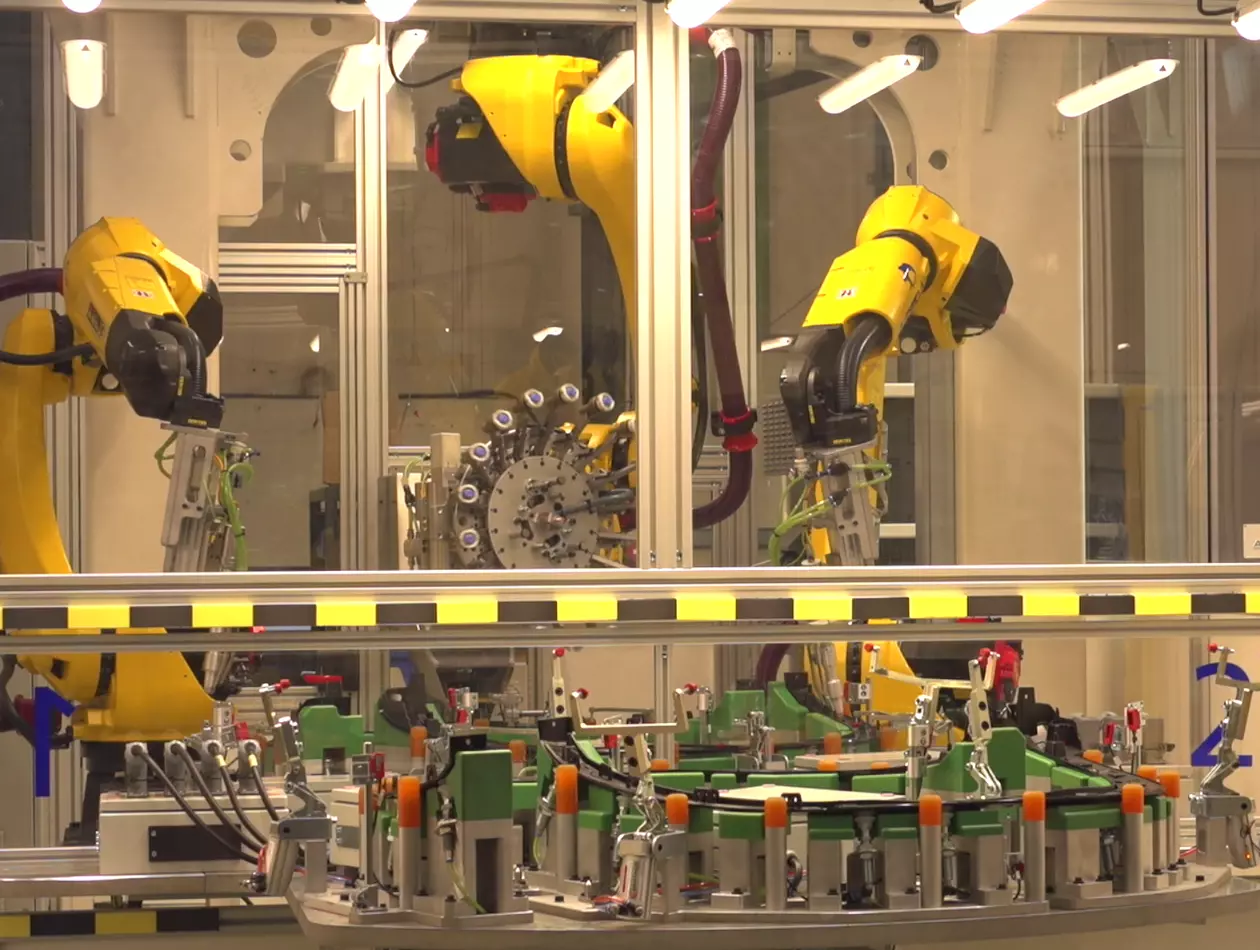

FANUC Robots Put Brose Sitech in the Driver’s Seat

Get Inspired

Les robots FANUC automatisent un processus automobile précis

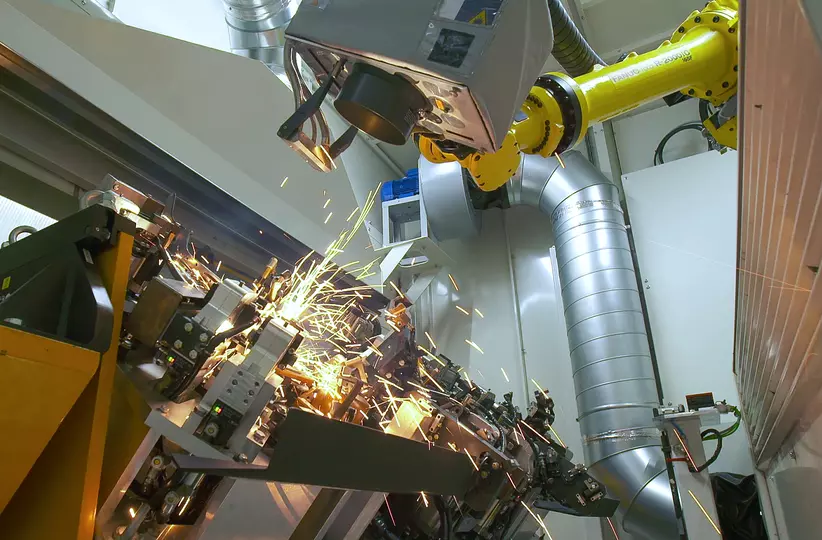

Les applications automobiles comptent parmi les tâches d'automatisation les plus exigeantes de toute l'industrie. Bien sûr, des vitesses d'axe rapides et une productivité élevée sont des paramètres clés, mais dans ce projet particulier, la précision et la répétabilité figuraient également en tête de liste des priorités. Face à ces exigences, ce sont les robots industriels FANUC qui se sont montrés à la hauteur.

AKE déploie des robots FANUC pour assurer le succès de Nexteer

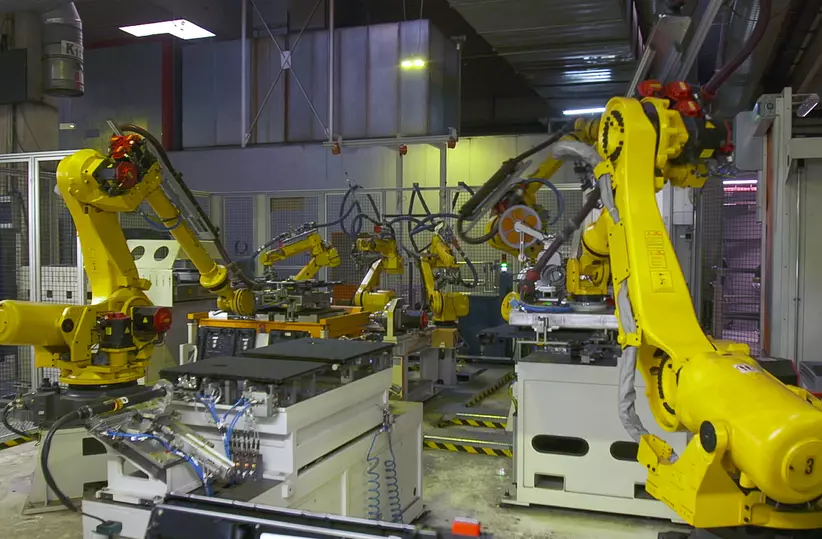

Nexteer Automotive profite de neuf robots industriels haute performance de FANUC pour automatiser la fabrication de composants de boîtiers de direction nécessaires à BMW. Installés par le spécialiste de l'automatisation des processus AKE Robotics, ces robots permettent à l'usine d'atteindre de nouveaux niveaux de productivité et de fiabilité.

Le cobot CRX de FANUC améliore la flexibilité de la production

Bonvicini Carpenteria bénéficie aujourd'hui de niveaux de qualité et de flexibilité encore plus élevés. L'entreprise peut varier entre les solutions d'automatisation chaque fois que les volumes de production l'exigent. Bonvicini Carpenteria profite notamment d'une programmation facile et rapide des robots grâce à des fonctionnalités telles que le glisser-déposer et une interface simple sur tablette.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Manutention

Soudage par points