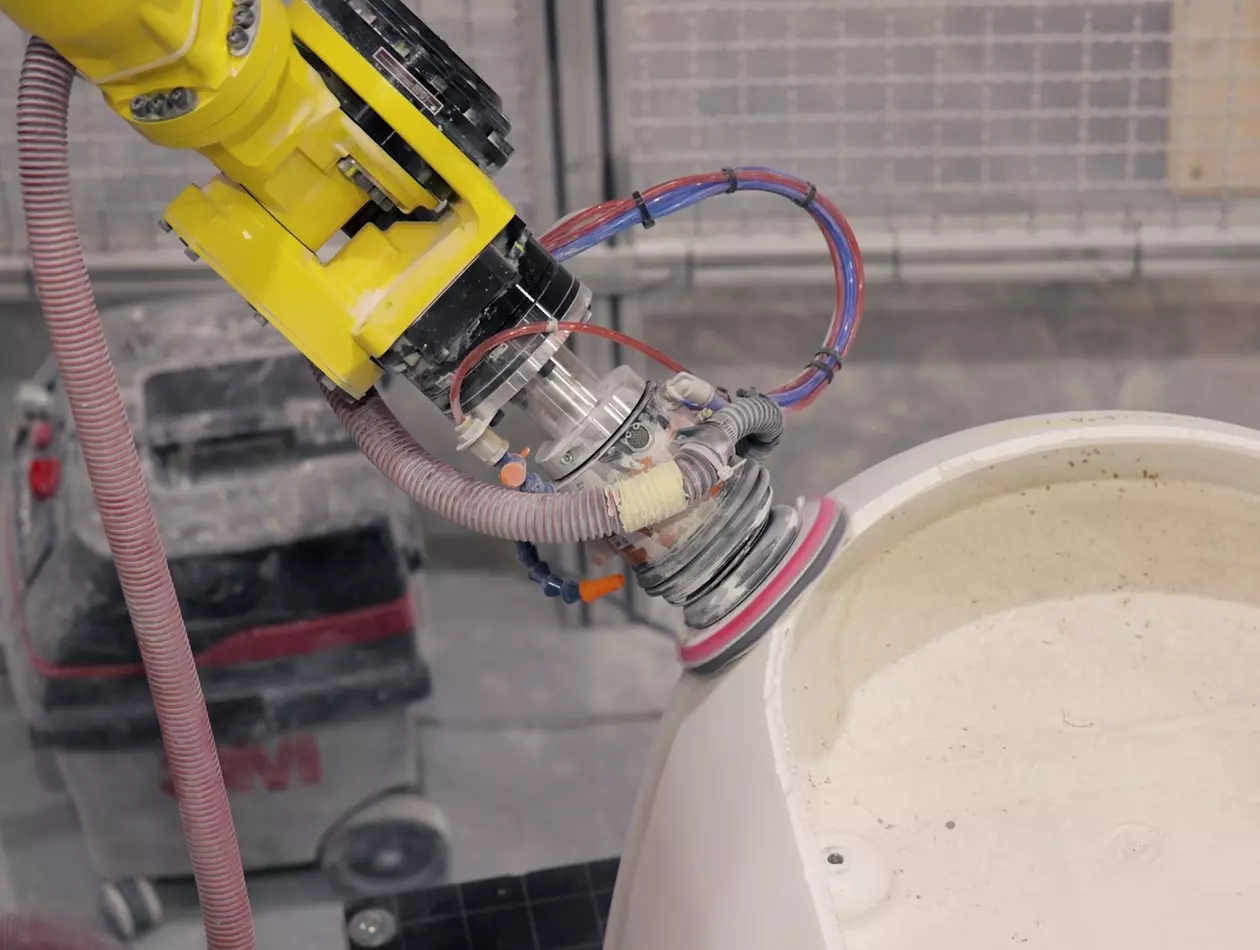

Fastlog AG Uses FANUC Robots for Industrial Polishing

Inspiriert werden

Sink and Bathtub Manufacturer Soaks Up the Benefits of FANUC Automation

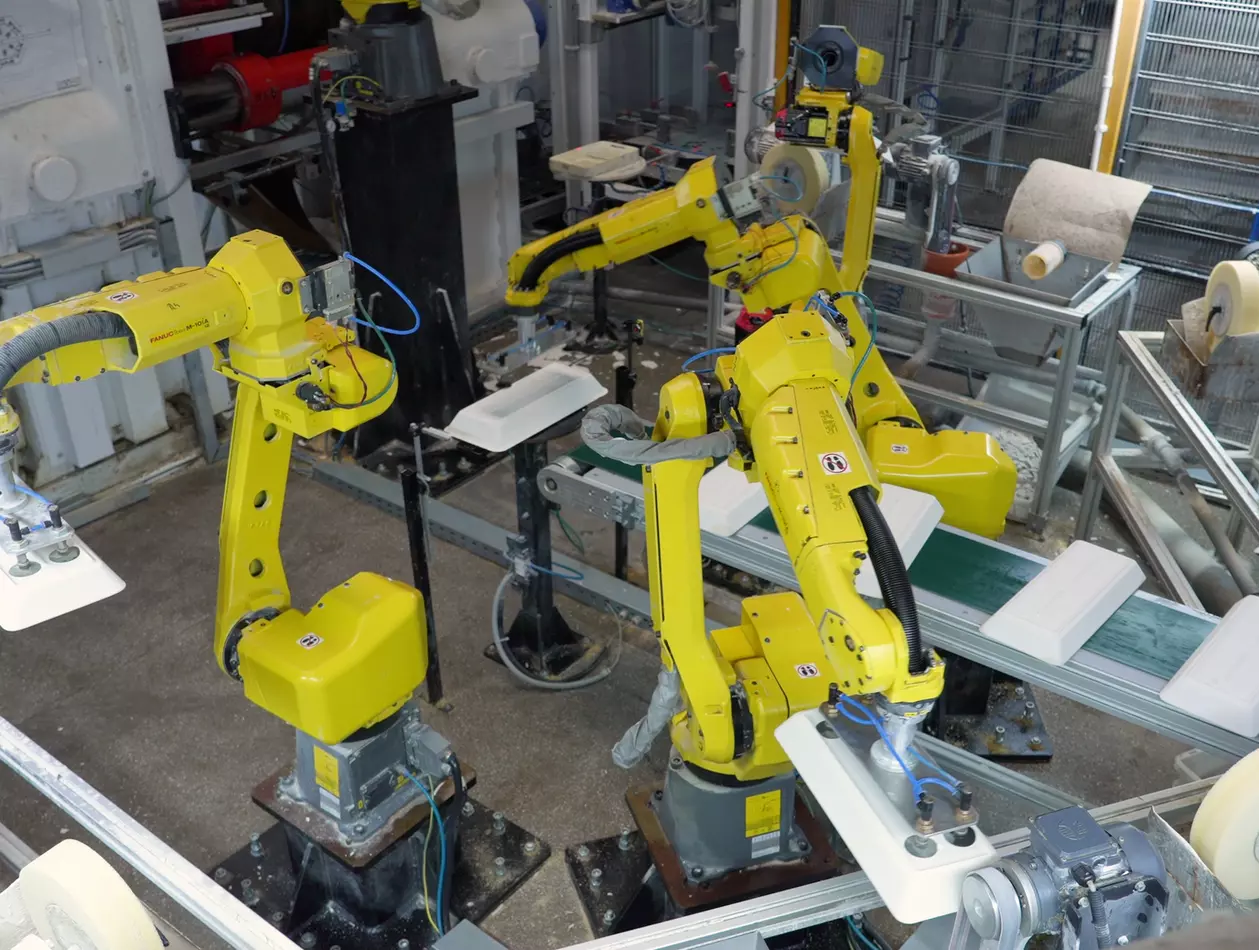

Many tasks throughout industry are tailor-made for automation. Grinding and polishing are among this number, particularly when challenging materials make these processes slow and onerous for human operatives.

Keramikwerk ist von der Leistungsfähigkeit der FANUC Roboter überwältigt

Wenn eine Fabrik ihren ersten FANUC Roboter installiert, sind die Vorteile so groß, dass in der Regel bald weitere Roboter folgen. Das beweist unter anderem der führende Keramikhersteller Apulum. Nach der Installation des ersten FANUC Roboters im Jahr 2014 haben seitdem mehrere weitere ihren Platz im Endbearbeitungsprozess des Unternehmens eingenommen. Apulum möchte nun seine Verpackungsprozesse mit FANUC Robotern erweitern.

FANUC Fallbeispiele

Entdecken Sie unser umfassendes Angebot an Fabrikautomatisierungslösungen, die in detaillierten Fallstudien vorgestellt werden und zur Optimierung und Rationalisierung von Fertigungsprozessen entwickelt wurden.

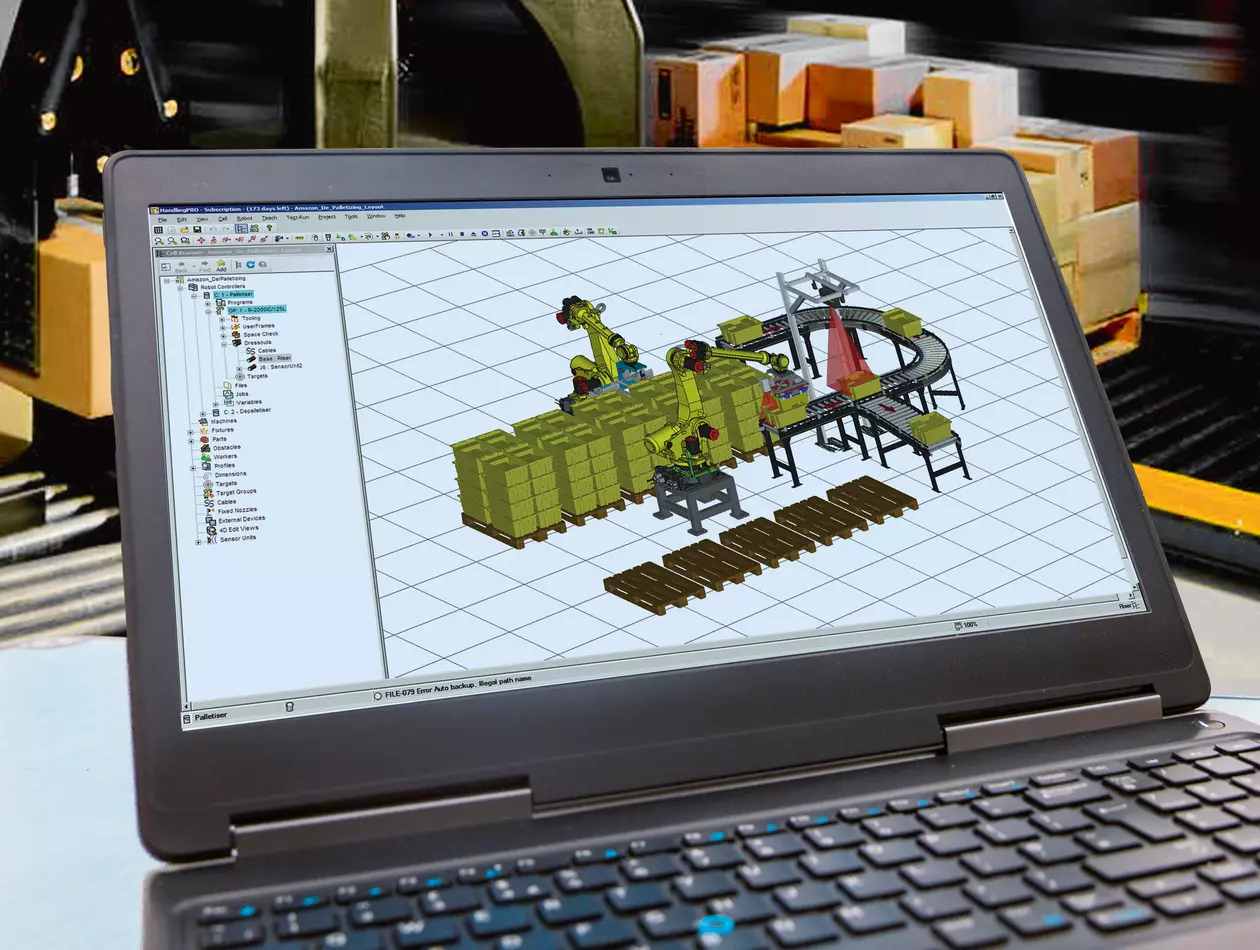

Palettierung