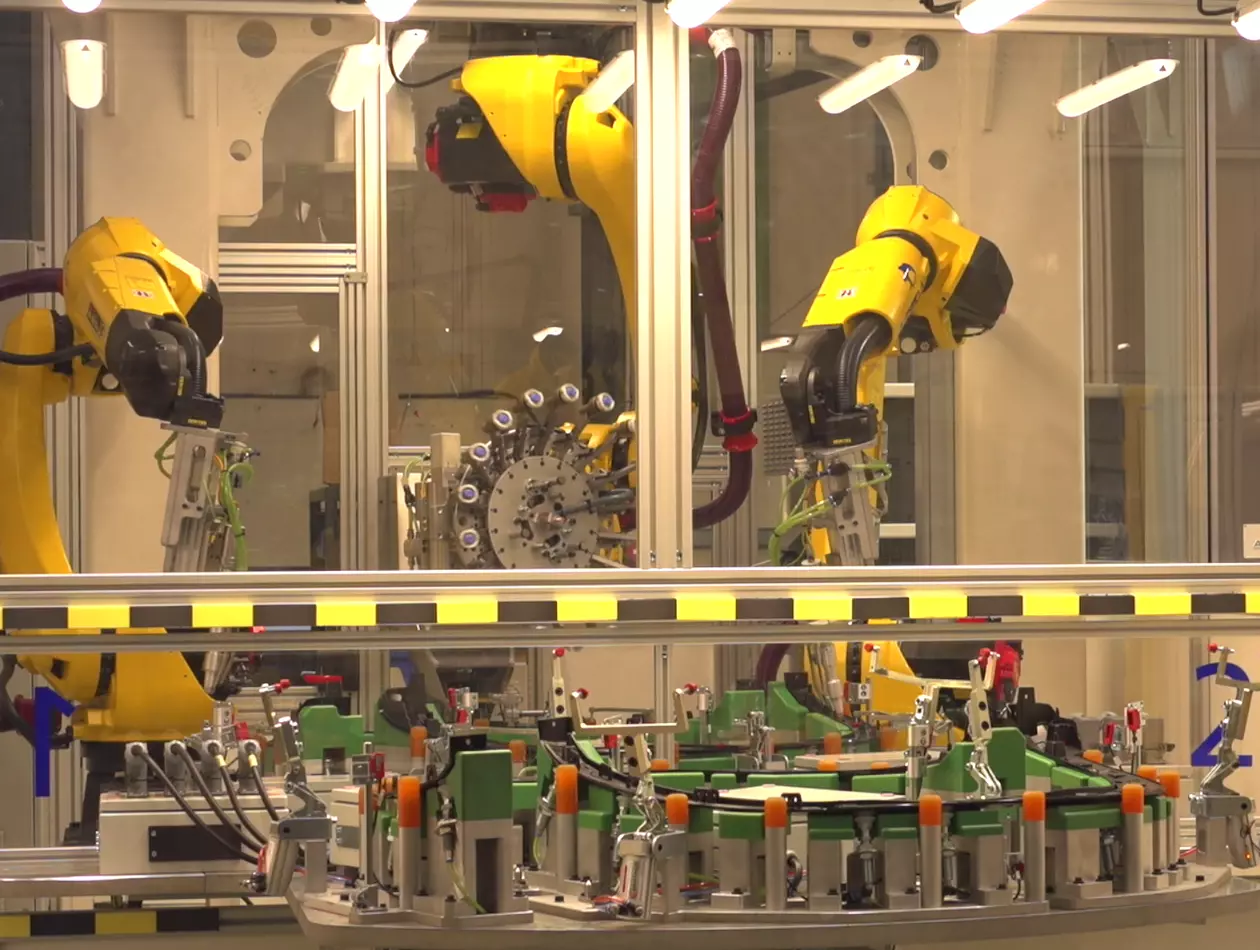

FANUC Robots Put Brose Sitech in the Driver’s Seat

Get Inspired

FANUC Robots Automate Precise Automotive Process

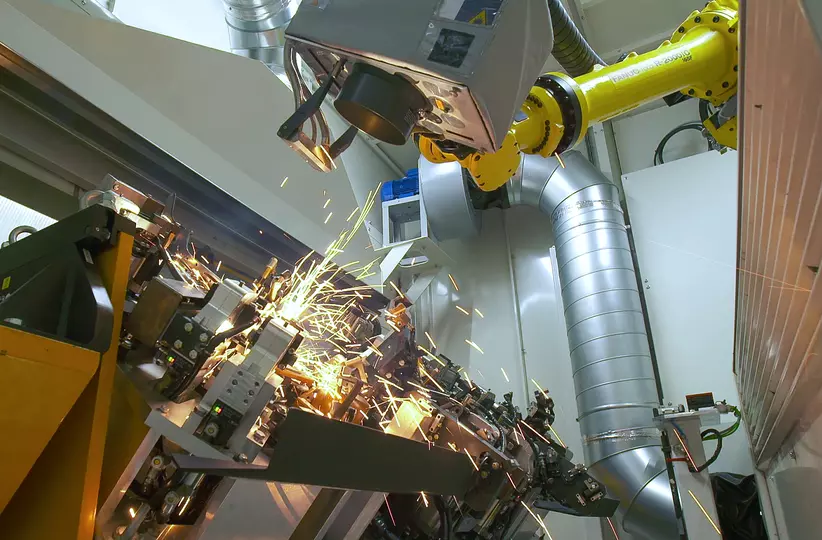

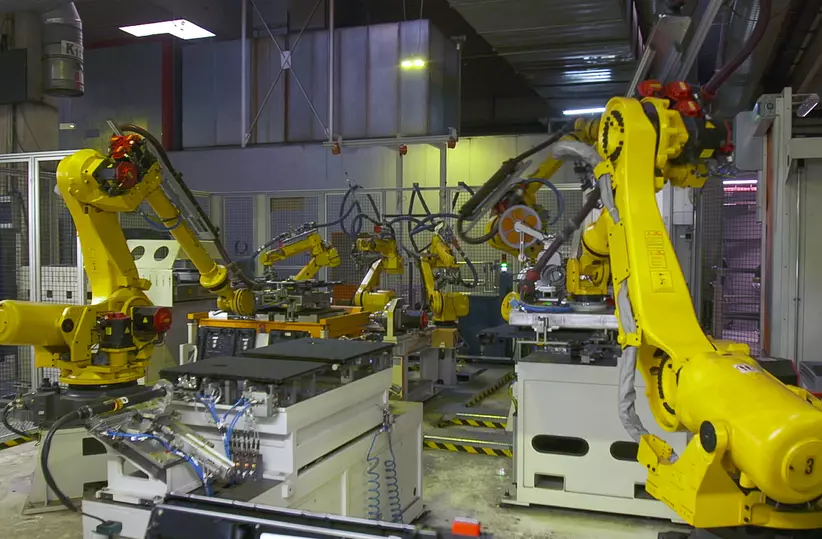

Automotive applications are among the most demanding automation tasks across all of industry. Sure enough, fast axis speeds and high productivity are key metrics, but in this particular project, precision and repeatability were also high on the list of priorities. With so many demands, it was FANUC industrial robots that stepped up to the mark.

AKE Deploys FANUC Robots to Steer Success at Nexteer

Nexteer Automotive is taking advantage of nine high-performance industrial robots from FANUC to automate the manufacturing of steering gear components required for BMW. Installed by process automation specialist AKE Robotics, the plant is seeing new levels of process productivity and reliability.

FANUC's CRX Cobot Boosts Production Flexibility

Bonvicini Carpenteria today enjoys even higher levels of quality and flexibility. The company can flex between automation solutions whenever production volumes dictate. In particular, Bonvicini Carpenteria is taking advantage of easy and fast robot programming with features such as drag and drop functionality and a simple tablet interface.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Material Handling

Spot Welding