Complex Machining for the Medical industry

Precision Crafting for Medical Products

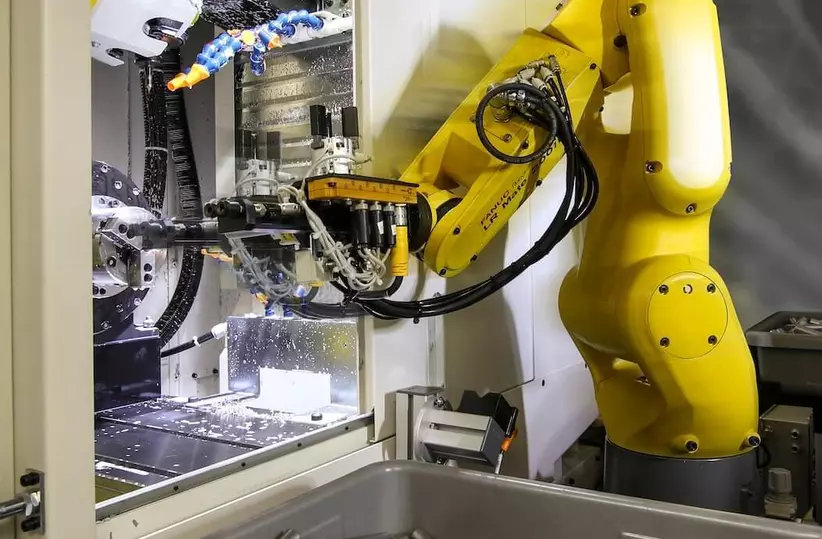

In the domain of medical manufacturing, where the margin for error is zero, complex machining stands as the pinnacle of precision and innovation. FANUC's CNC, ROBODRILL, and ROBOCUT technologies deliver this exactitude, transforming blocks of raw materials into life-saving medical devices and implants. These systems represent the peak of reliability and efficiency, ensuring that every curve, angle, and edge complies with the most stringent medical standards. As we delve into the specifics of these advanced machining solutions, we reveal how FANUC is shaping the future of medical manufacturing with unparalleled precision and adaptability.

- Application

- Related products

- Benefits

Precision Engineering in Medical Manufacturing

FANUC's advanced CNC systems, ROBODRILL, and wire EDM solutions are essential for the complex machining of high-tech medical devices. Specialised for metal parts, our technologies handle a wide range of materials including stainless steel, aluminium, and ceramics with exceptional accuracy. Optimised for 5-axis machining, our systems produce intricate geometries and high-quality finishes critical for medical implants and equipment. Fully compliant with strict hygiene and clean room standards, FANUC's reliable and efficient solutions ensure minimal downtime and meet the high precision requirements of the medical manufacturing sector.

Precision Milling with FANUC CNC

Advanced 5-Axis Capabilities with ROBODRILL

High-Speed Drilling and Tapping

Precision Wire Cutting with ROBOCUT

Seamless Integration with FANUC CNC

Precision Milling with FANUC CNC

FANUC CNC systems enhance the precision milling of complex medical components by utilising advanced control technologies that ensure high accuracy and surface finish. Our CNC systems are ideal for handling a variety of materials used in medical manufacturing, from plastics to exotic metals, ensuring tight tolerances that are crucial for medical devices.

Advanced 5-Axis Capabilities with ROBODRILL

FANUC’s ROBODRILL provides superior 5-axis machining options, enhancing the ability to produce complex geometries with a single setup. This reduces handling time and improves overall accuracy of the final product. Smooth TCP and TWP functions ensure precise tool path control and high surface quality, pivotal for the exacting standards of medical manufacturing.

High-Speed Drilling and Tapping

The ROBODRILL excels in high-speed drilling and tapping, offering exceptional precision and rapid cycle times. Its high-speed spindle supports very small diameter tools, essential for the intricate details required in medical instruments and implants. This capability is crucial for manufacturers looking to optimise productivity without compromising on quality.

Precision Wire Cutting with ROBOCUT

FANUC’s ROBOCUT wire EDM machines are tailored for creating intricate components used in surgical instruments and implants. With features like automatic threading and high reliability, ROBOCUT ensures detailed accuracy and repeatability in shapes that are challenging to achieve with other machining processes, making it an indispensable tool in medical manufacturing.

Seamless Integration with FANUC CNC

FANUC CNC systems allow for quick robotisation, enabling seamless integration of robotics into existing production lines. This adaptability is vital for manufacturers seeking to increase automation and reduce manual labor, particularly in high-volume or high-precision tasks. The ability to quickly adapt and automate with FANUC solutions means better consistency and scalability in medical manufacturing.

Our Products for Complex Machining

Benefits for your Industry

Precision and Performance

Enhanced Reliability

Customisable Control

Advanced Material Handling

Rapid Cycle Times

Surface Excellence

Precision Wire EDM

Automated Efficiency

Reliability in Production

Our Solutions for Other Industries

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.