Warehousing, Logistics, Post & Parcel

Automation Solutions for Warehouses, Fulfilment Centers and Supply Chain Distribution

As the e-commerce market expands, supply chains face escalating demands and labor shortages. FANUC's automation solutions enable cobots and robots to efficiently handle picking, packing, and palletising, improving uptime, delivery delays, workplace accidents, and manual mistakes.

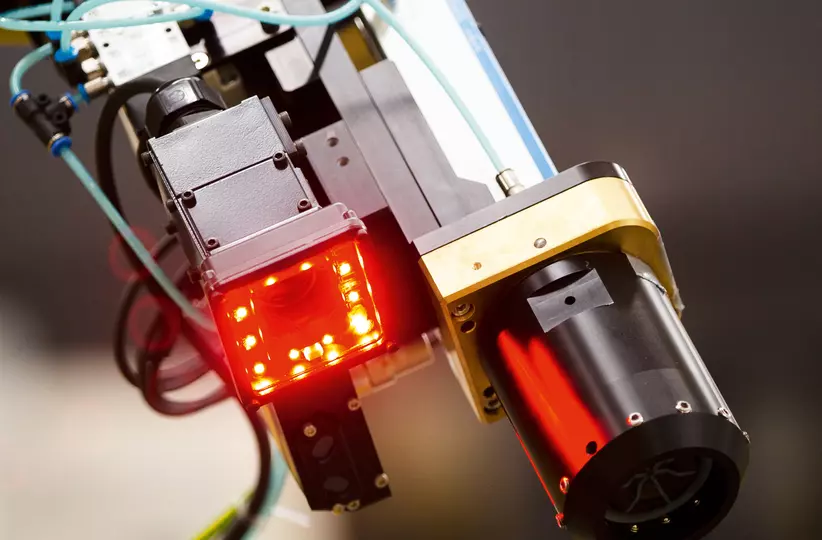

By integrating FANUC's advanced technology, businesses can boost throughput, maintain quality during peak periods, and adapt to changing demands. Equipped with cutting-edge sensors and vision systems, FANUC robots handle diverse products with precision and care.

These automation solutions also support workplace safety by minimising the need for manual labor in repetitive and heavy tasks, fostering a more satisfied and engaged workforce. FANUC's technology transforms supply chain operations, helping companies stay competitive in the dynamic e-commerce landscape.

- Application

- Related Products

- Benefits

- Case Studies

Robotics & Automation for the Warehousing & Logistics Industry

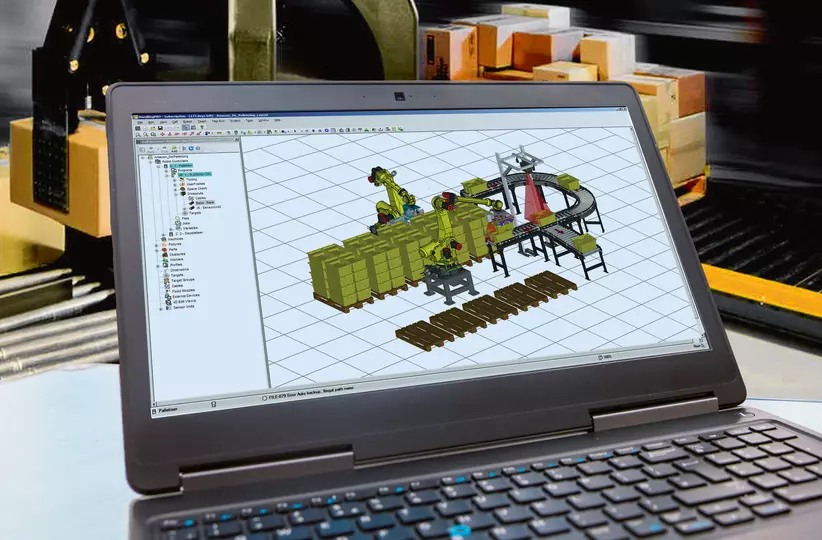

No matter the application you are looking to automate, we have the right solution. Our robots and cobots, equipped with seamless and easy-to-connect vision systems, and our dedicated software options, ensure precise handling and optimal efficiency, enhancing productivity and reducing costs.

Depalletising

Picking, Singulation & Induction

Sortation

Labelling

Decanting & Box Cutting

Co-Packing

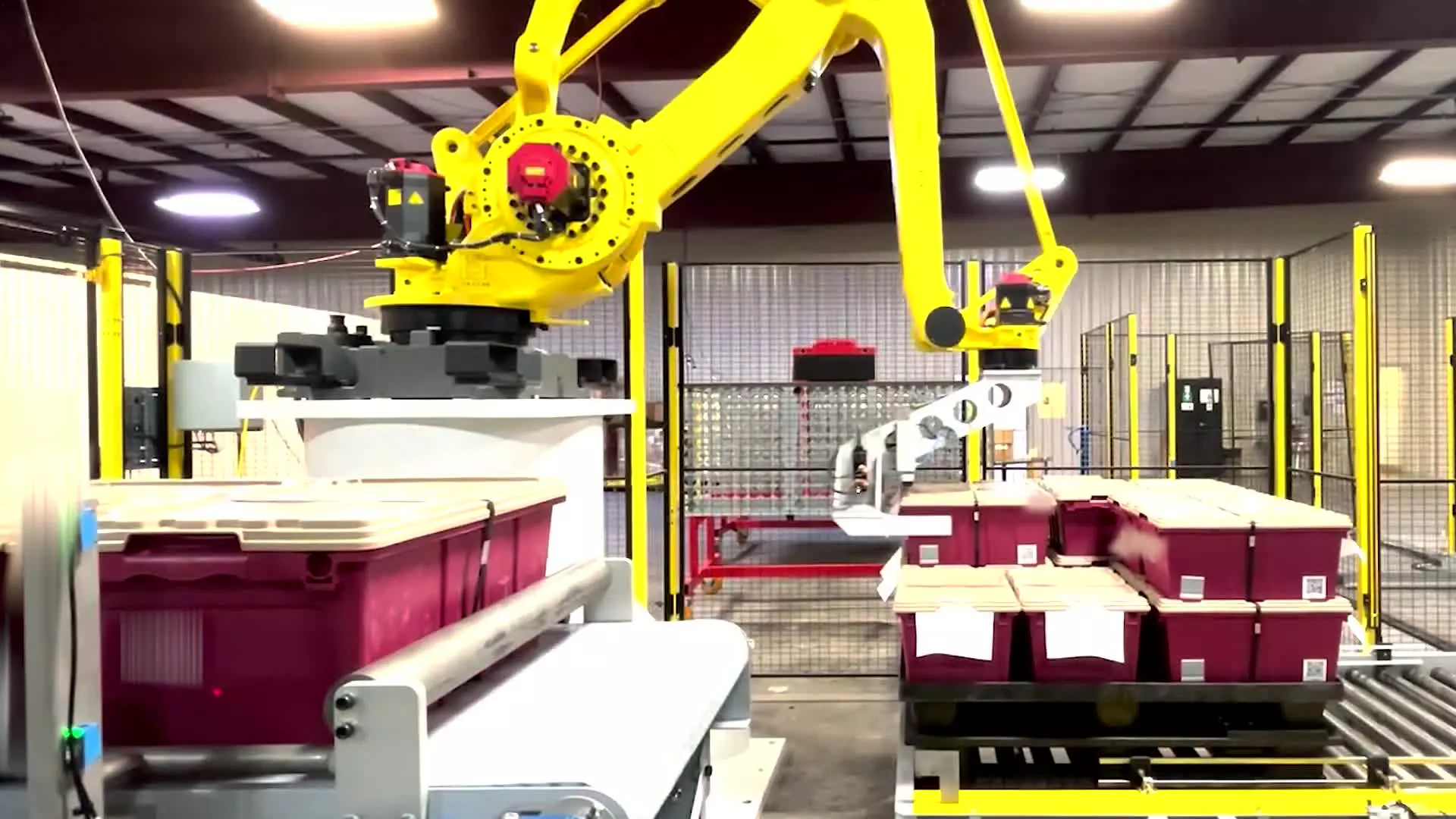

Palletising

Truck Unloading

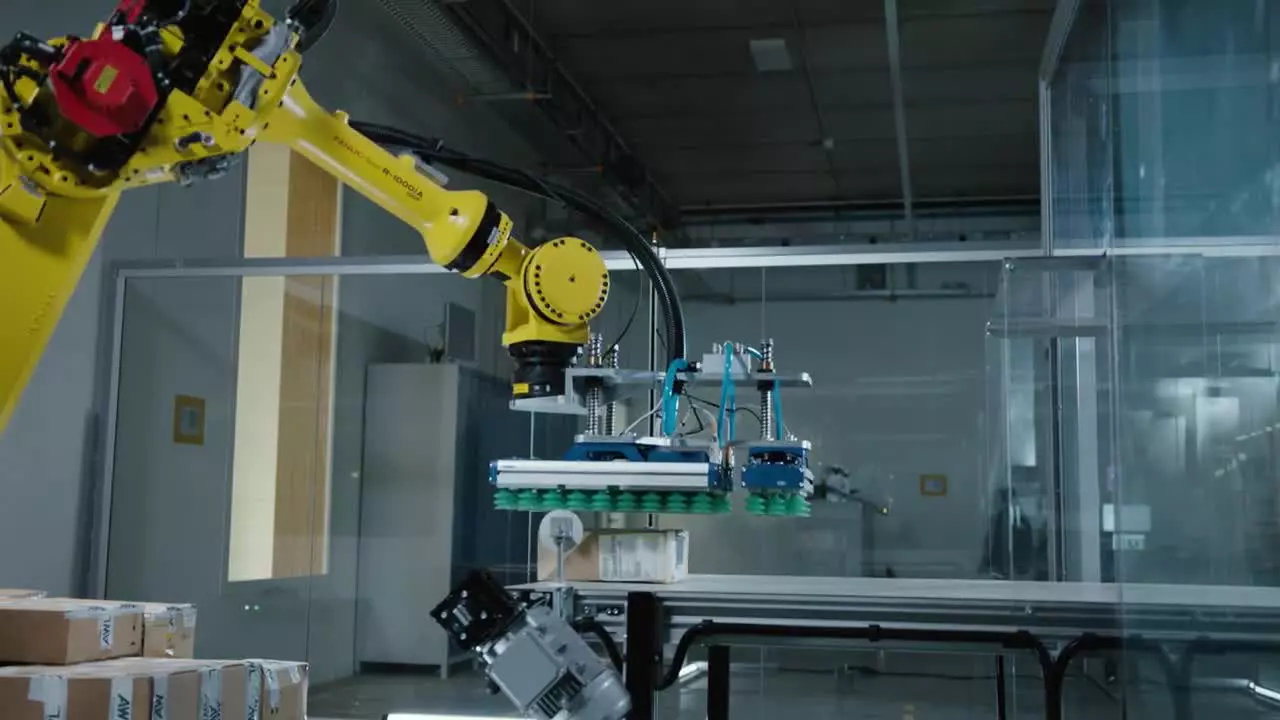

Depalletising

Automate the process of unloading pallets with our solutions. Using 𝑖RVision, our robots and cobots can handle mixed depalletising, unloading materials of varying weights, shapes, and sizes without interruption, resulting in improved efficiency and faster output.

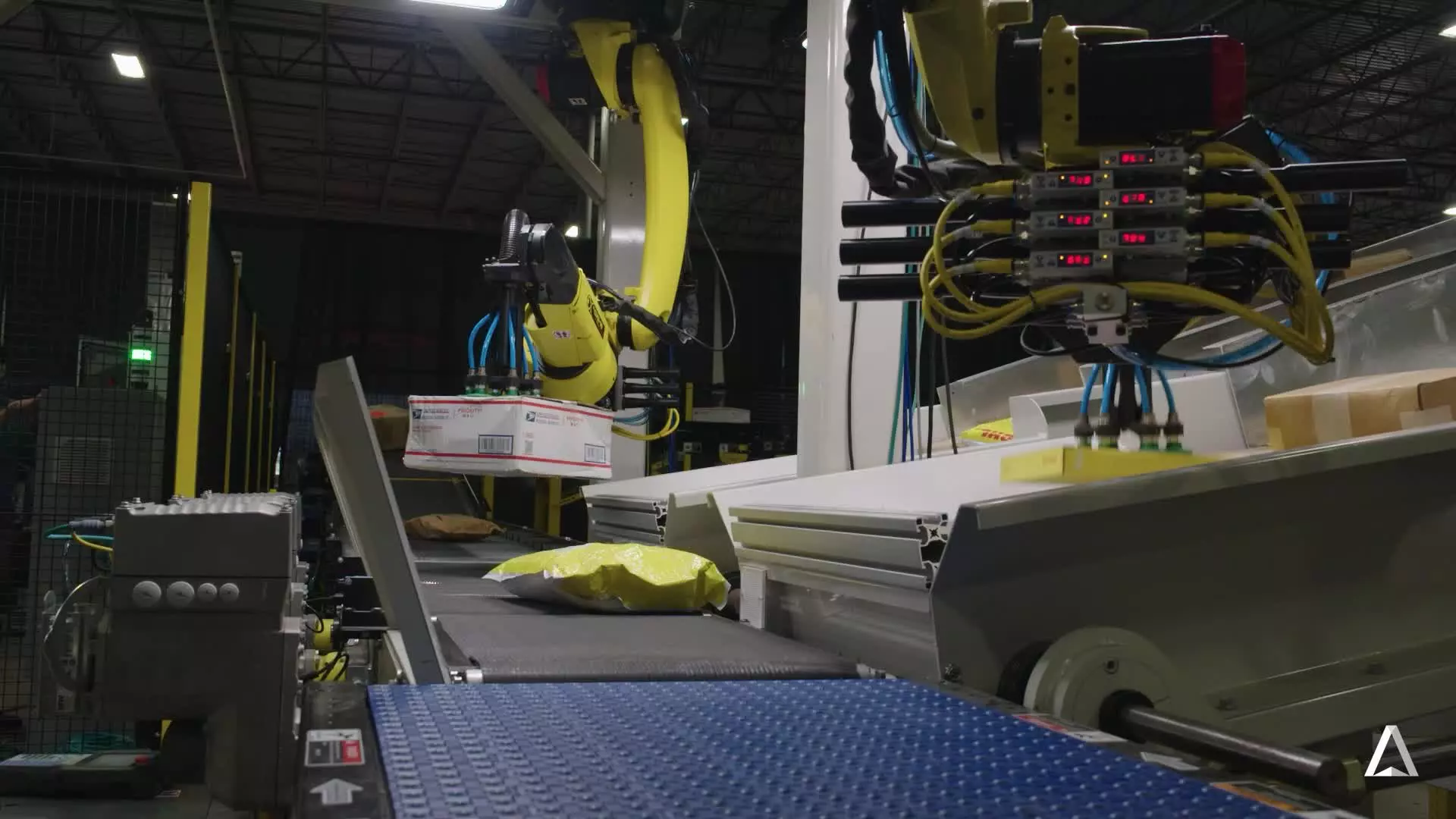

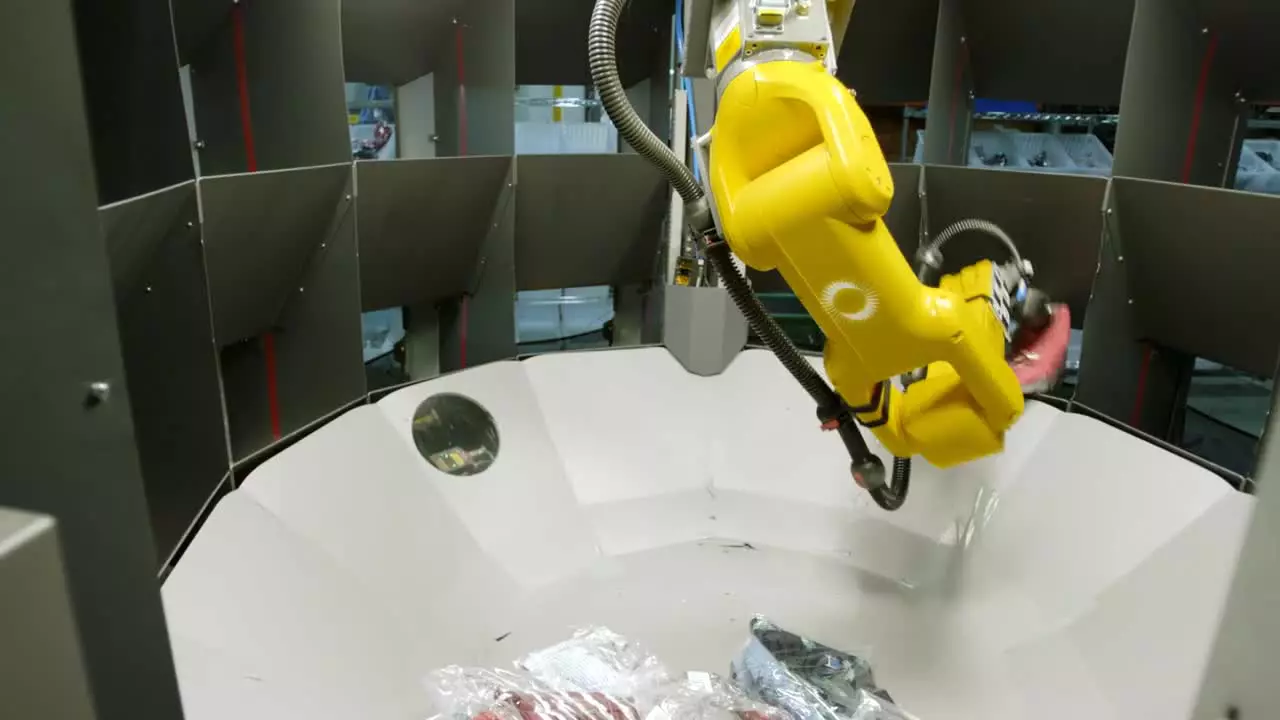

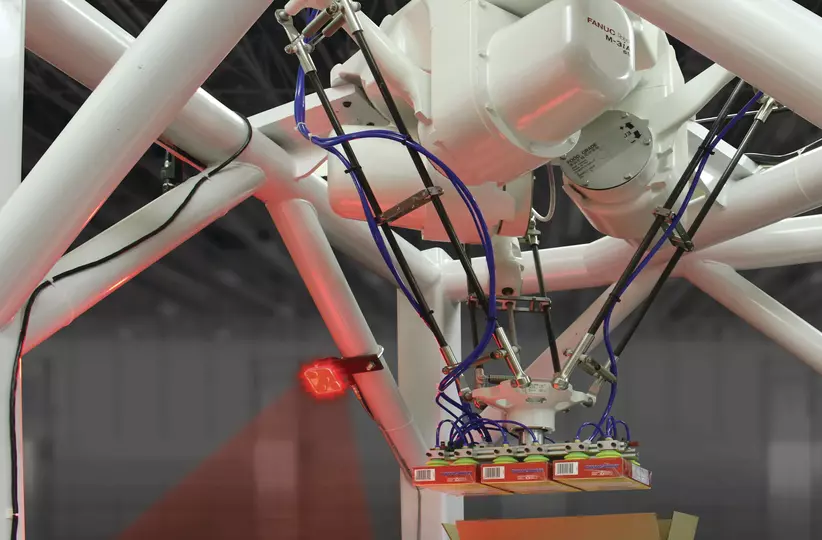

Picking, Singulation & Induction

FANUC robots play a key role in continuous picking of goods from totes (Goods to Robot) and managing a diverse range of stock keeping units (SKUs). Additionally, the use of warehouse robots for singulation and induction can limit the need for tedious manual labour and reduce the risk of injury and error.

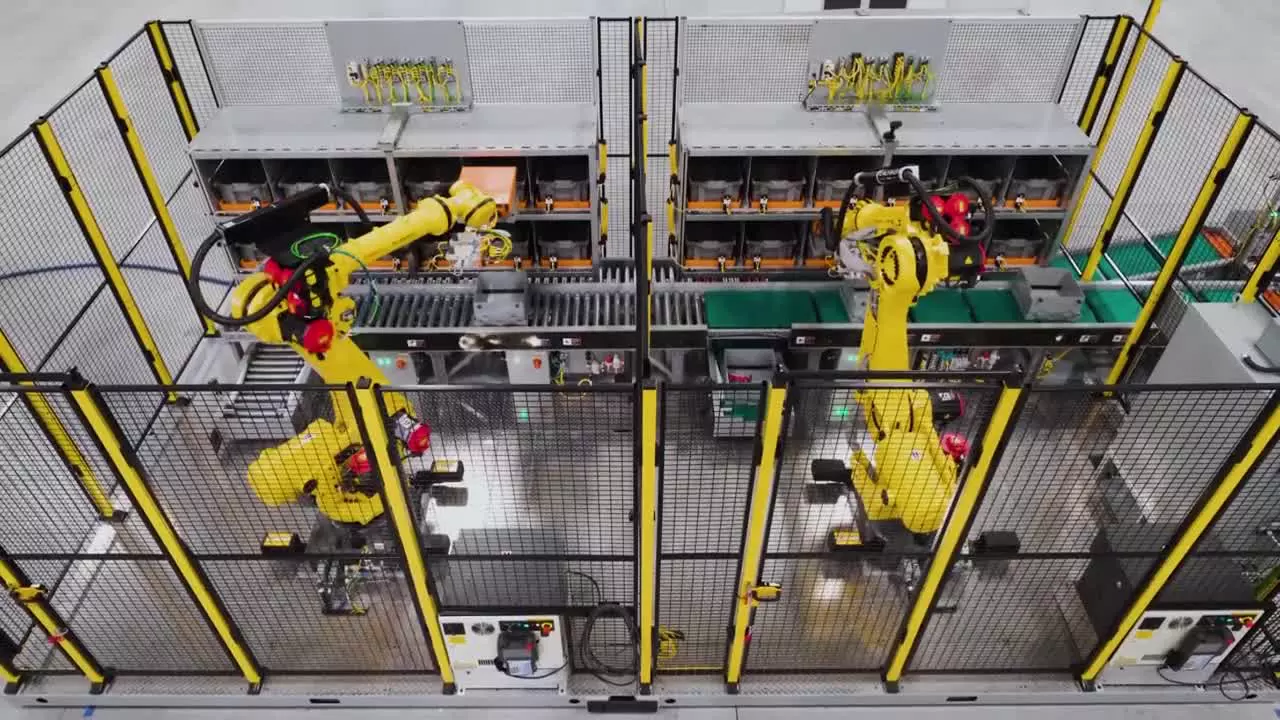

Sortation

FANUC robots excel in sortation applications by efficiently sorting and organising various items based on predetermined criteria. They accurately handle diverse products, optimising operations and streamlining sorting. From parcels to inventory, FANUC robots deliver precise performance, enhancing productivity and throughput.

Labelling

Automating the print and apply of labels with FANUC cobots and robots can significantly boost speed, throughput, and productivity by accurately labelling thousands of containers per hour on multiple surfaces.

Decanting & Box Cutting

Turn logistics operations safer for your staff by automating hasardous decasing and decanting applications of chemicals or grains, with our robots, for a safer and cost-effective solution.

Co-Packing

FANUC's robotic solutions for co-packing improve production rates, ergonomic safety, and profits, effectively addressing the diminished efficiency and profitability faced by co-packers handling many mixed SKUs.

Palletising

Robots and cobots make palletising more efficient through automation. Our flexible warehousing robots support productivity with optimised palletising processes and patterns. Additionally, the easy implementation of dedicated software and visual monitoring systems ensures seamless integration and real-time oversight.

Truck Unloading

Reduce product damage during the handling process, keep workers safe minimising strenuous tasks and significantly speed up the turnaround time, by implementing FANUC robots and cobots to automate this part of the fulfilment process.

Our Robot Offer

Highlights

𝑖RVision

Collaborative Robots

Simulation

Maximise Production Uptime

Benefits for your Industry

Increased Efficiency

Enhanced Productivity

Cost Savings

Improved Safety

Enhanced Quality Control

Flexibility

Quick Adaptability

Space Optimisation

Scalability

Lifecycle Support

Choosing FANUC Enabled Packaging Solutions Company to Open Up New Business Opportunities

Our Solutions for Other Industries

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.