Nissan

FANUC Robots Optimise High-Volume Production at Nissan

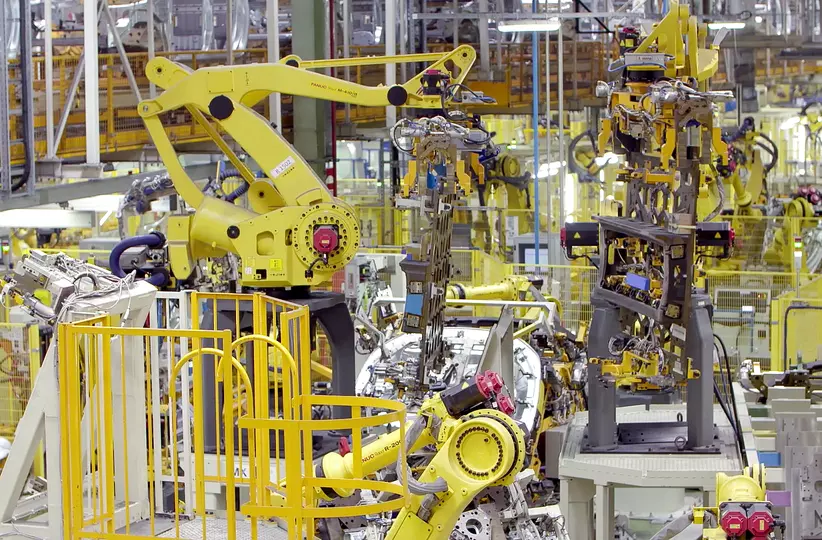

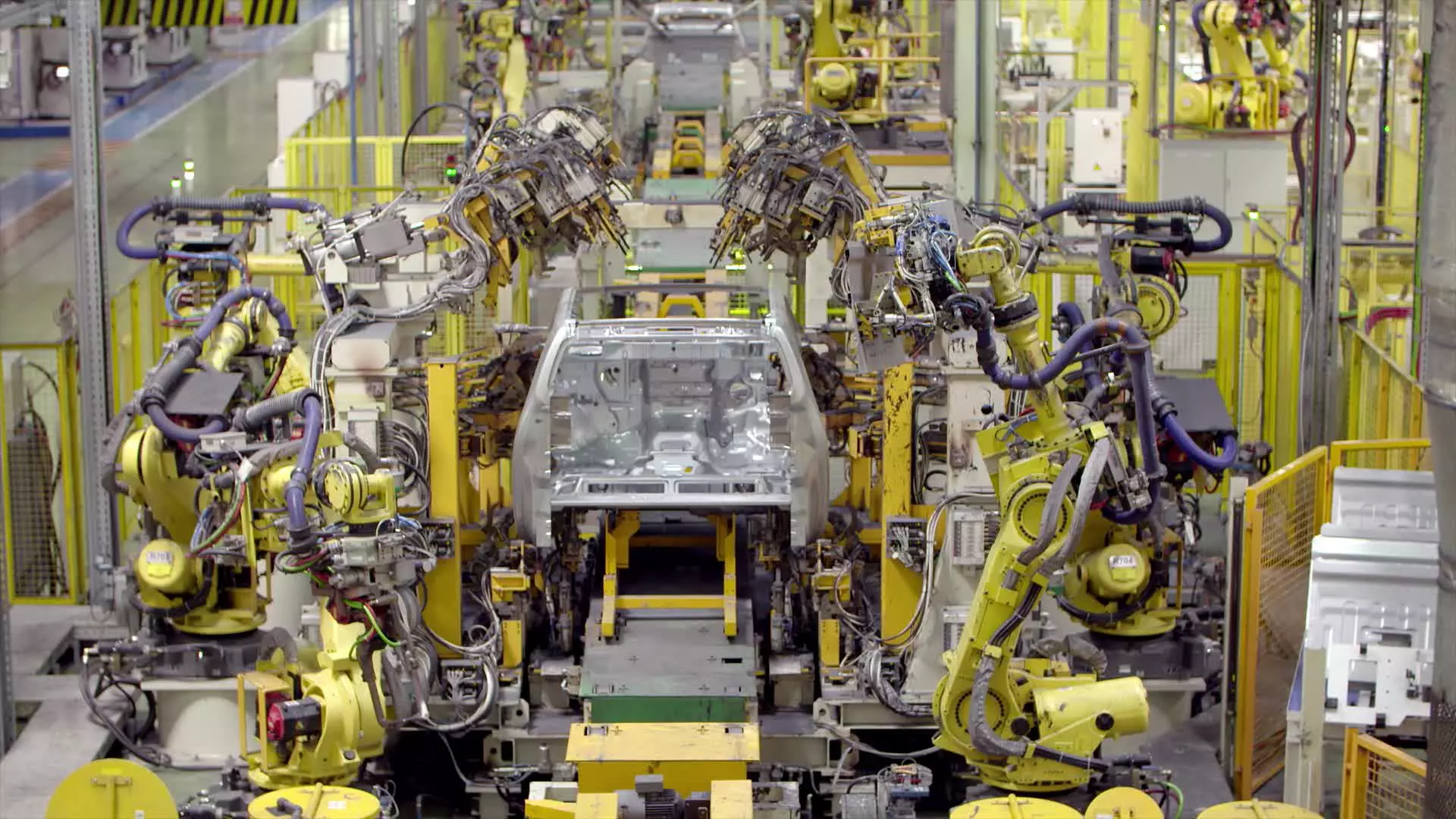

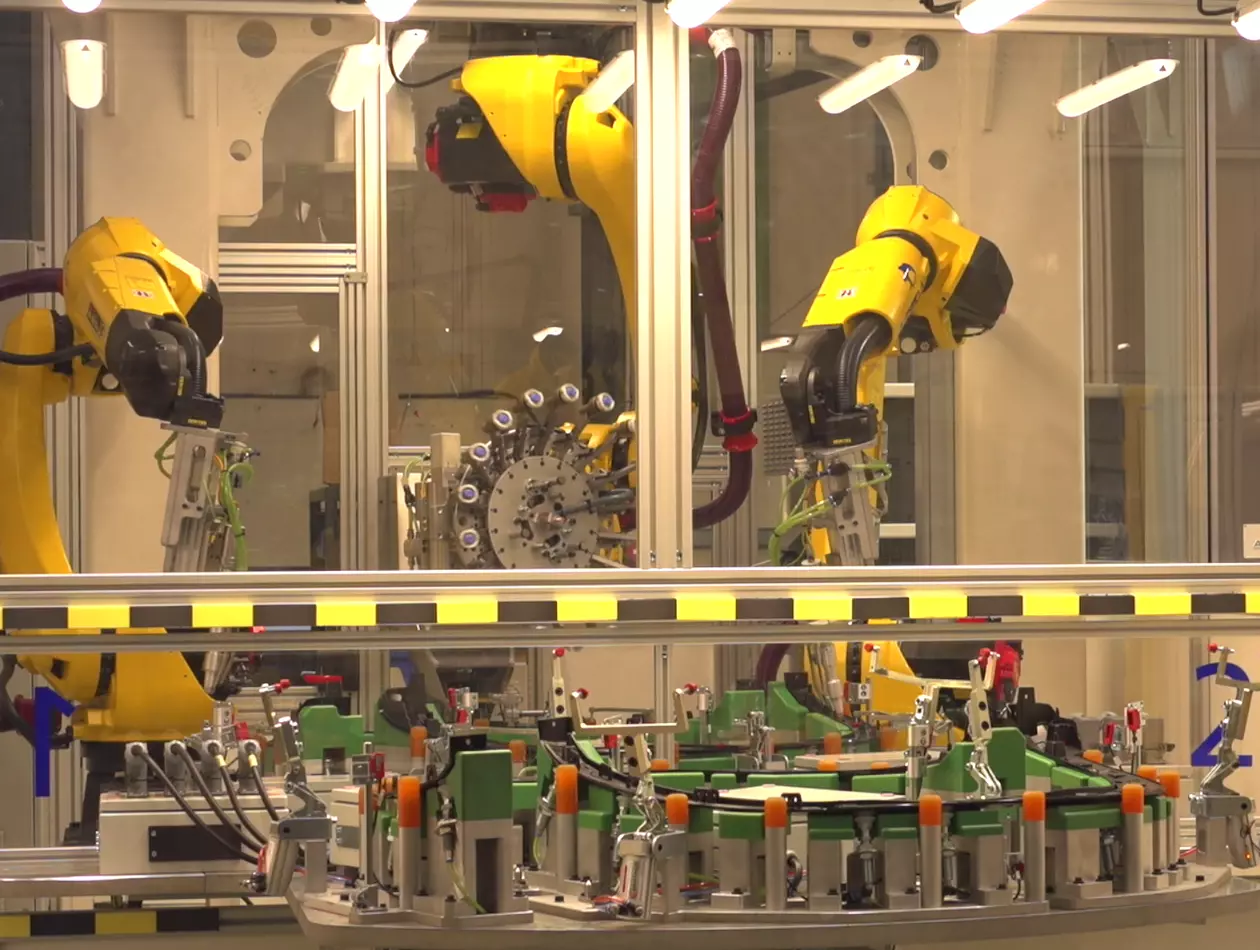

Industrial robots have become an integral part of the modern automotive production line. Each task they perform is vital, not only to meet the necessary levels of efficiency and productivity, but also to meet the highest standards of quality and safety. FANUC is the robot of choice for many of the world’s leading automotive giants, with Nissan providing a notable case in point.

Paylaş

Car manufacturing with FANUC robots ensures process security and reliability.

FANUC robots offer easy integration with other production systems.

Dedicated trainings for maintenance employees help them to excel.

FANUC punctual service (preventitive maintenance and hotline service) supports maximum plant uptime.

Get Inspired

AGFRA

FANUC Robotları Hassas Otomotiv Süreçlerini Otomatikleştiriyor

Otomotiv uygulamaları, tüm endüstriler arasında en titiz otomasyon görevleri arasındadır. Hızlı eksen hızları ve yüksek verimlilik elbette önemli ölçütlerdir, ancak bu özel projede hassasiyet ve tekrarlanabilirlik de öncelikler listesinin üst sıralarında yer almaktaydı. Bu kadar çok talebin olduğu bir durumda, FANUC endüstriyel robotları bu görevi başarıyla yerine getirdi.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Malzeme Taşıma

Endüstriyel robotlarla malzeme taşımayı otomatikleştirerek işletmeniz için sayısız avantaj elde edin. Manuel taşıma için gereken zaman ve çabayı azaltarak verimliliği ve üretkenliği önemli ölçüde artırın. Robotların yorulmadan kesintisiz çalışmasını sağlayarak tutarlı performans elde edin, hataları en aza indirin, daha yüksek verim ve daha hızlı işlem süreleri elde edin.

Ark Kaynağı

Endüstriyel robotlarla ark kaynağı prosesinizi otomatikleştirerek hassasiyeti ve tutarlılığı artırın, yüksek kaliteli kaynaklar elde edin. Yorulmadan kesintisiz çalışarak ve üretim süresini kısaltarak verimliliğinizi artırın. Tehlikeli dumanlara ve aşırı sıcağa maruz kalmayı en aza indirerek güvenliği artırın. Ayrıca, işçilik maliyetlerini azaltarak ve yeniden işleme ihtiyacını azaltarak maliyet verimliliği elde edin.

Otomotiv Endüstrisi için Robotik ve Otomasyon

Otomotivde mükemmellik: FANUC'un çok yönlü otomasyon çözümleri.