Advanced Injection Moulding for the Automotive Industry

Comprehensive Injection Moulding for Superior Automotive Components

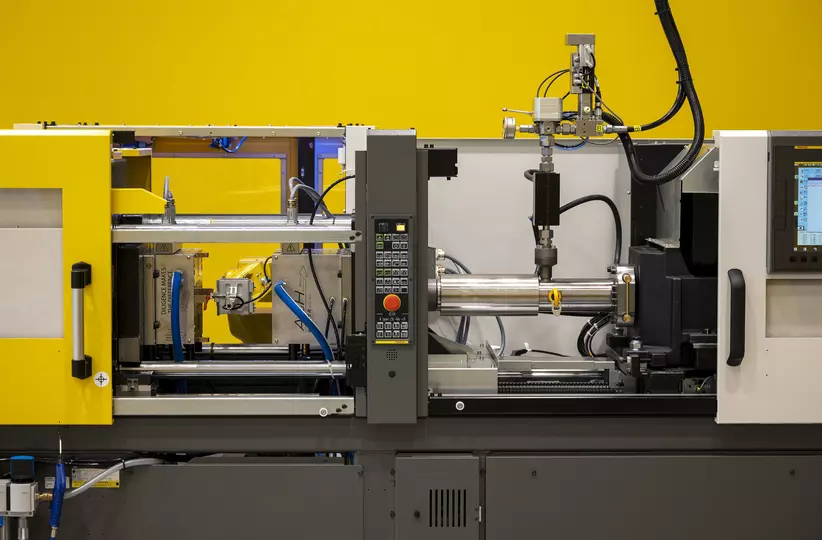

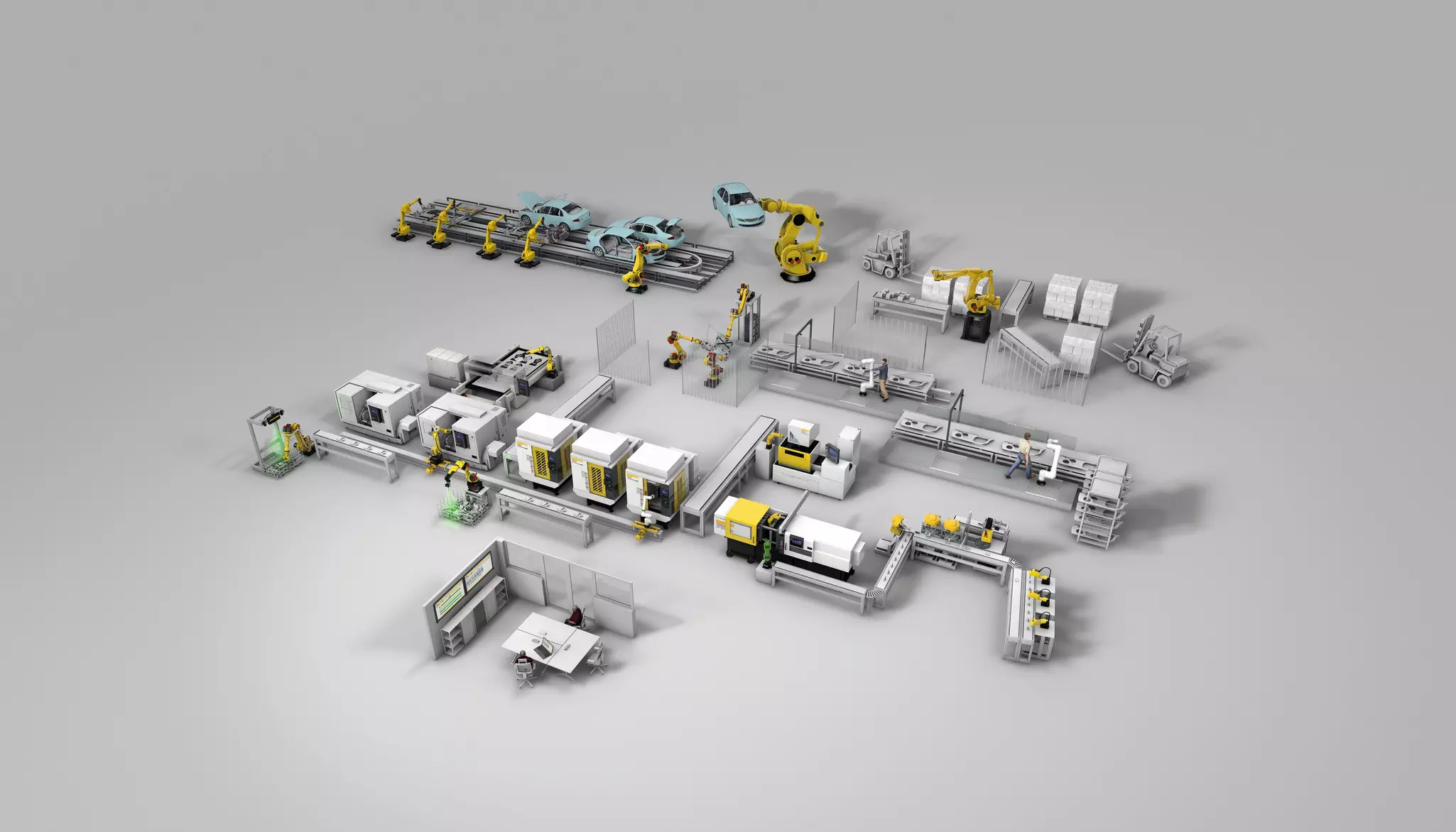

FANUC enhances automotive production with comprehensive injection moulding solutions, covering everything from standard moulding, insert moulding, overmoulding, precision and optical parts to LSR technologies. Our offering extends beyond machines from 15T up to 500T, to include sophisticated automation systems, improving efficiency and quality for a variety of components. This combination of state-of-the-art machinery and seamless automation supports the industry's high standards for interior, exterior, and optical components. With FANUC, advancing innovation in automotive manufacturing becomes a tangible achievement.

- Application

- Related products

- Benefits

- Case Studies

Precision and Versatility in Automotive Production

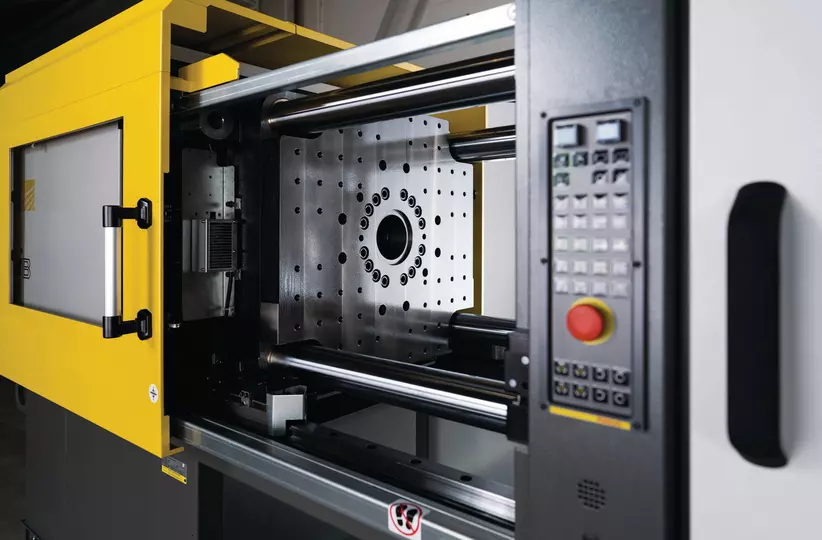

Equipped with specialised functions to tackle challenges like gas venting and variations in plasticising time and volume, FANUC's ROBOSHOT excels in high-volume production of automotive components. Recognised as the market's most reliable machine, ROBOSHOT consistently produces impeccable parts quickly and requires minimal maintenance. Its adaptability to frequent production shifts in the automotive industry is unmatched, thanks to the availability of six different screw sizes. This feature ensures ROBOSHOT's unparalleled versatility, allowing manufacturers to achieve a wide range of tasks with a single machine, streamlining operations and enhancing efficiency. On top of that ROBOSHOT's have advanced power regeneration feature enables intelligent energy recovery: This represents a huge saving both in terms of CO₂ emissions and energy bills.

Precision Engineered Parts

Highest Design Quality

Flawless Optical Components

Multi-Material Moulding

Insert Moulding

Over Moulding

In-Mould Labeling

LSR Moulding

Sustainability and CO₂ emission

Precision Engineered Parts

FANUC ROBOSHOT is the right solution for moulding precision-engineered parts like gears, bearings, and other critical components used in the automotive assembly. The high-speed and accuracy of ROBOSHOT contribute to the reliable manufacturing of these intricate and essential parts.

Highest Design Quality

Automotive interior components, such as dashboard trims, buttons, and panels, require precise moulding to meet design specifications. FANUC ROBOSHOT's advanced control and monitoring capabilities help achieve consistent quality in the production of interior elements and complex parts, like connectors.

High Precise Automotive Parts Moulding

Flawless Optical Components

For applications involving optical components like lenses and light guides in automotive lighting systems, ROBOSHOT's precision ensures the moulding of parts with exceptional clarity and minimal defects, meeting the stringent quality standards required in the automotive industry.

Optical Parts Moulding

Multi-Material Moulding

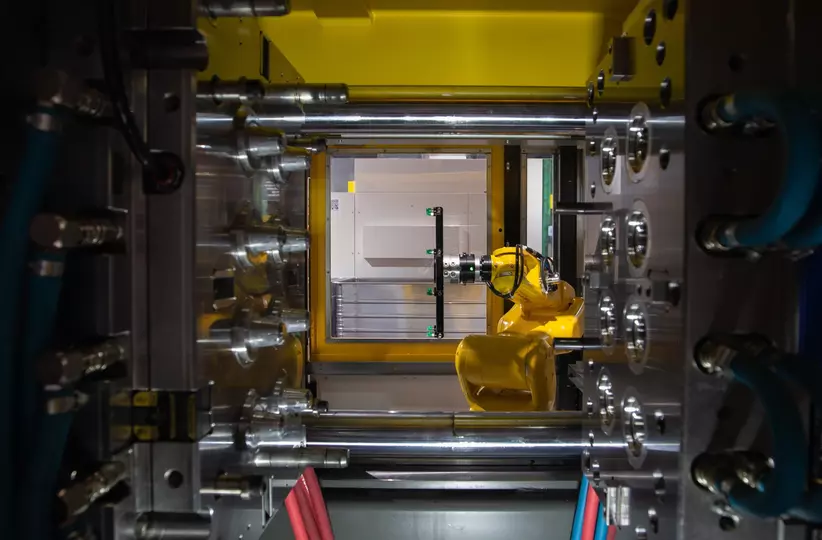

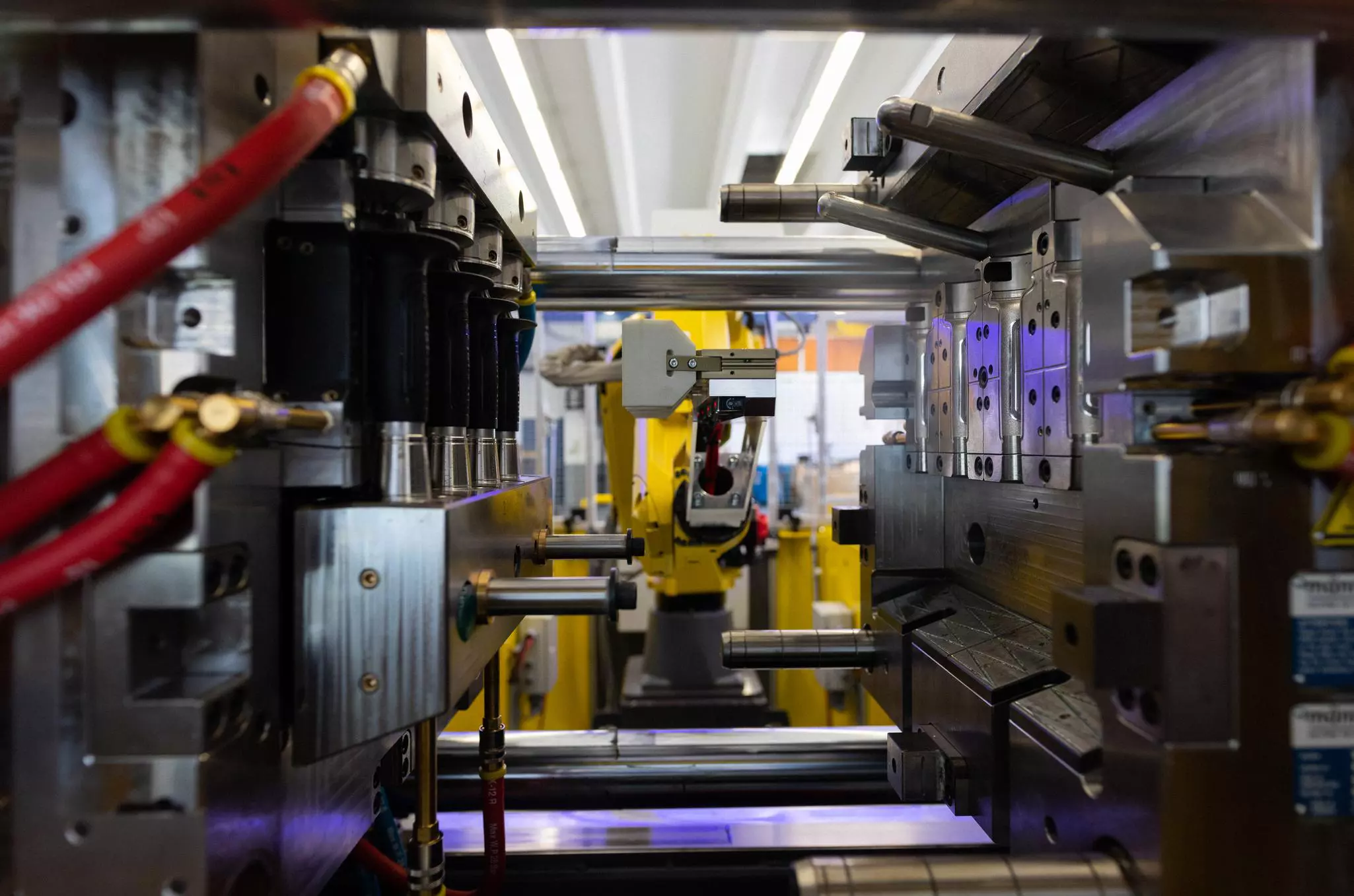

ROBOSHOT's versatility extends to multi-material moulding, allowing for the production of automotive components with different materials in a single mould. This capability is beneficial for creating hybrid parts with varying properties, such as combining rigid and flexible materials.

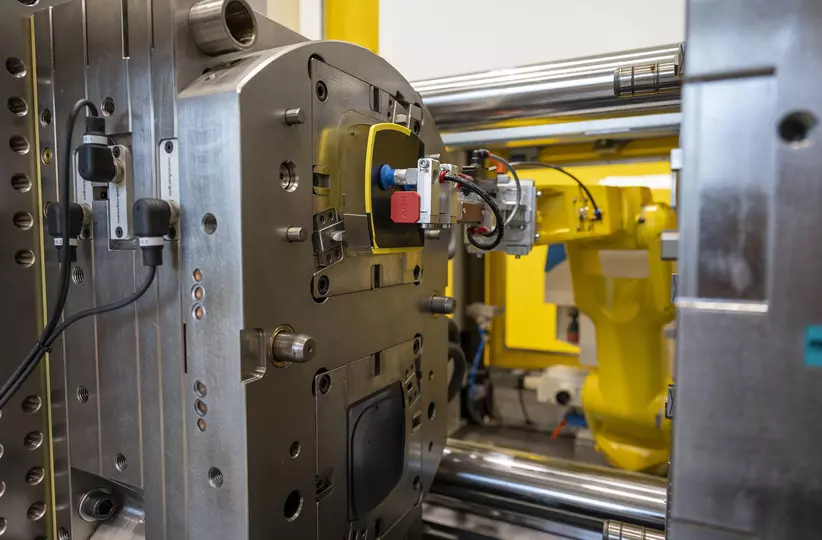

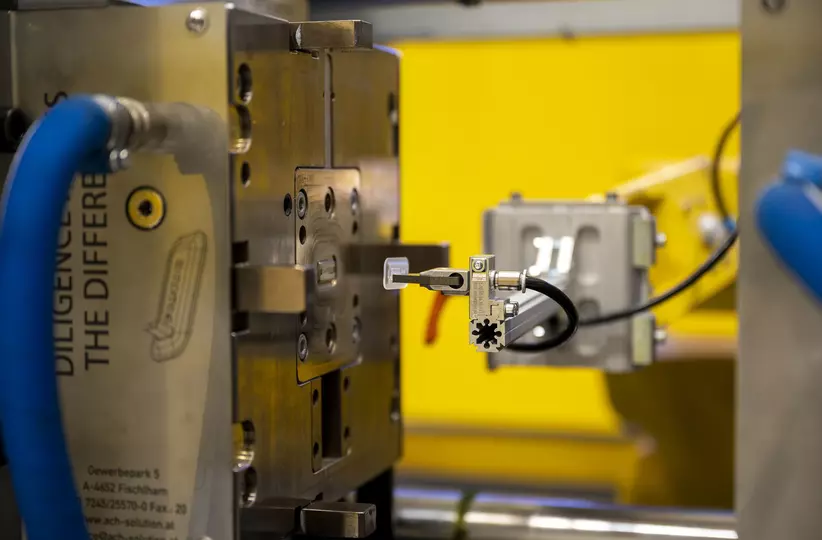

Insert Moulding

FANUC's ROBOSHOT excels in insert moulding applications, offering precision and reliability for embedding metal parts into molded plastic with exceptional accuracy.

Over Moulding

FANUC's ROBOSHOT delivers outstanding performance in overmoulding applications, seamlessly bonding different materials for durable, high-quality automotive components.

Automated Production of a Tool Handle

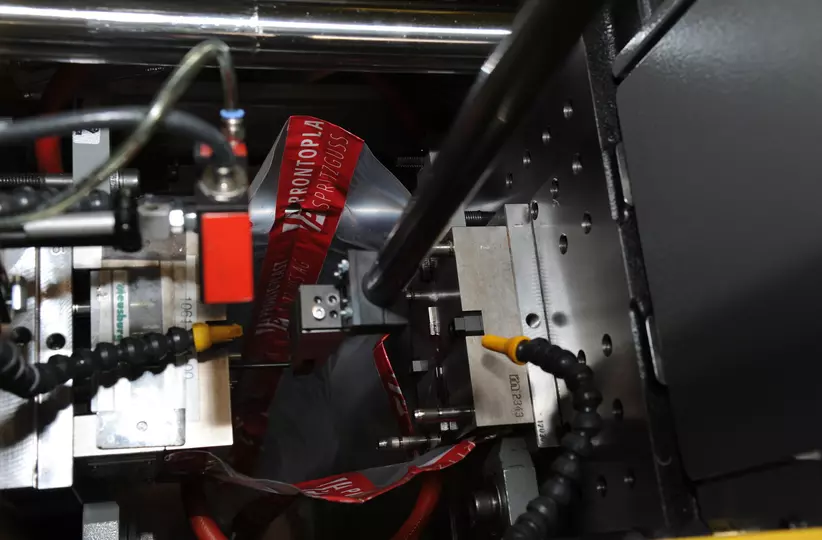

In-Mould Labeling

FANUC's ROBOSHOT enhances in-mould labeling (IML) applications, ensuring precise and efficient integration of labels within plastic components for high-definition finishes.

LSR Moulding

FANUC's ROBOSHOT excels in LSR applications, offering unparalleled accuracy and consistency in liquid silicone rubber moulding.

Sustainability and CO₂ emission

With the 100% electric-driven axes technology, FANUC ROBOSHOT provides you with maximum energy efficiency and minimal CO₂ emissions.

Our ROBOSHOT Injection Moulding Machines

ROBOSHOT 𝛼-S100𝑖B

ROBOSHOT 𝛼-S130𝑖B

ROBOSHOT 𝛼-S150𝑖B

ROBOSHOT 𝛼-S150𝑖B Small Capacity

ROBOSHOT 𝛼-S30𝑖B

ROBOSHOT 𝛼-S220𝑖B

Benefits for your Industry

Unsurpassed Precision

Remarkable Efficiency

Consistent Quality

Adaptable Flexibility

Reliability

Smart Connectivity

Automation-Ready

Injection Moulding Shop Shapes its Future with FANUC

There are numerous plastic injection moulding machines available on the market, but most modern manufacturers seek a core set of key attributes based on flexibility, energy efficiency and performance. As a result, the highly capable FANUC ROBOSHOT, with its potential for rapid tool changes and all-electric low energy consumption, is a proven choice for any manufacturer of plastic products looking to become more competitive and gain market share. Among those able to provide testimony is Hungary-based Viskiplast.

FANUC ROBOSHOT Machines Keep Things Simple for SIMON

High-volume plastics parts; thin walls; zero defects; short automotive lead times; demanding energy efficiency requirements. A growing number of manufacturers are combatting these common challenges by investing in ROBOSHOT high-performance, all-electric injection moulding machines from FANUC. Among their number is SIMON Plastics.

Our Solutions for Other Industries

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.