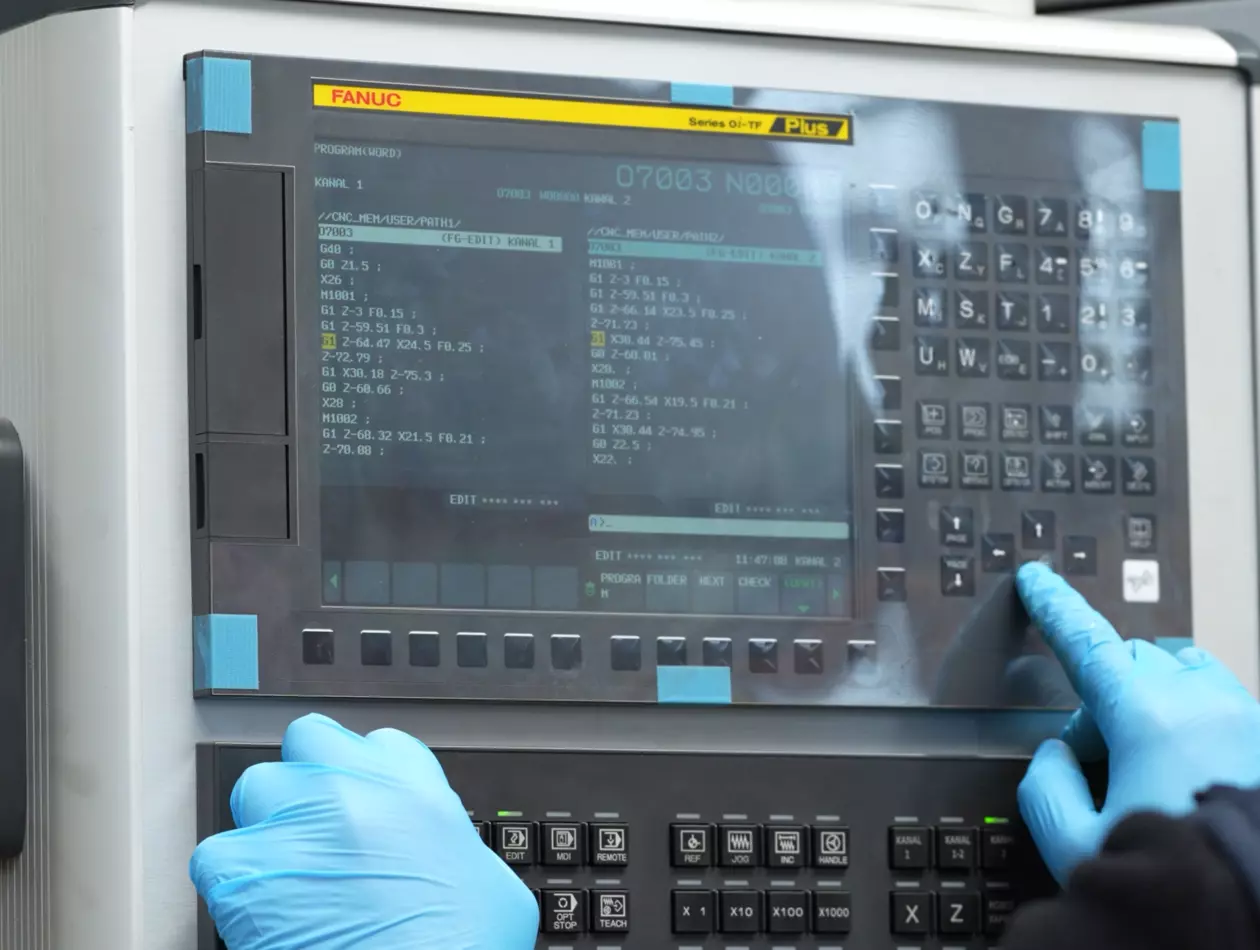

0𝑖-TF Plus

Get Inspired

Get Inspiration from Other's Success

CNC Lathe Builder Takes Control of Production with FANUC

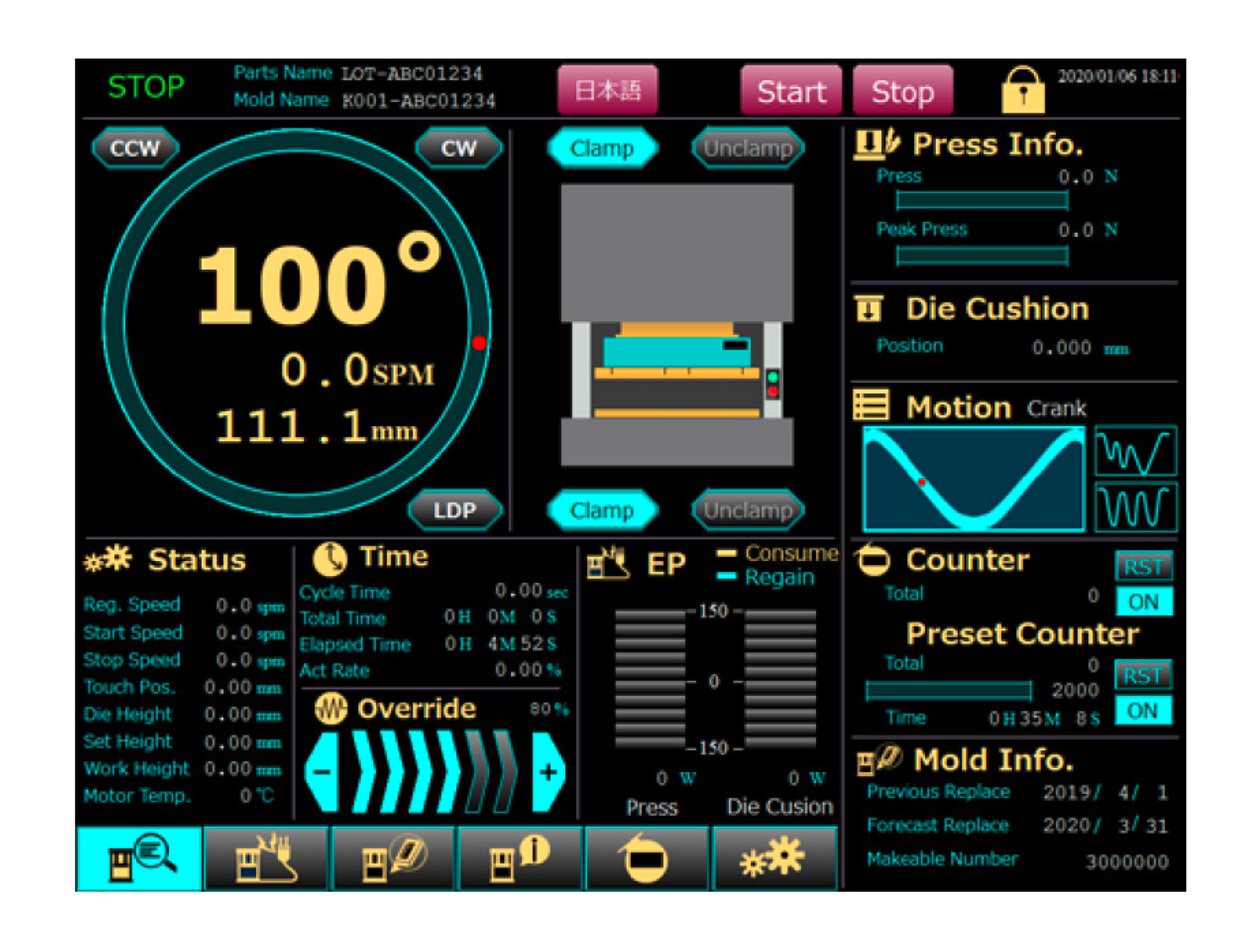

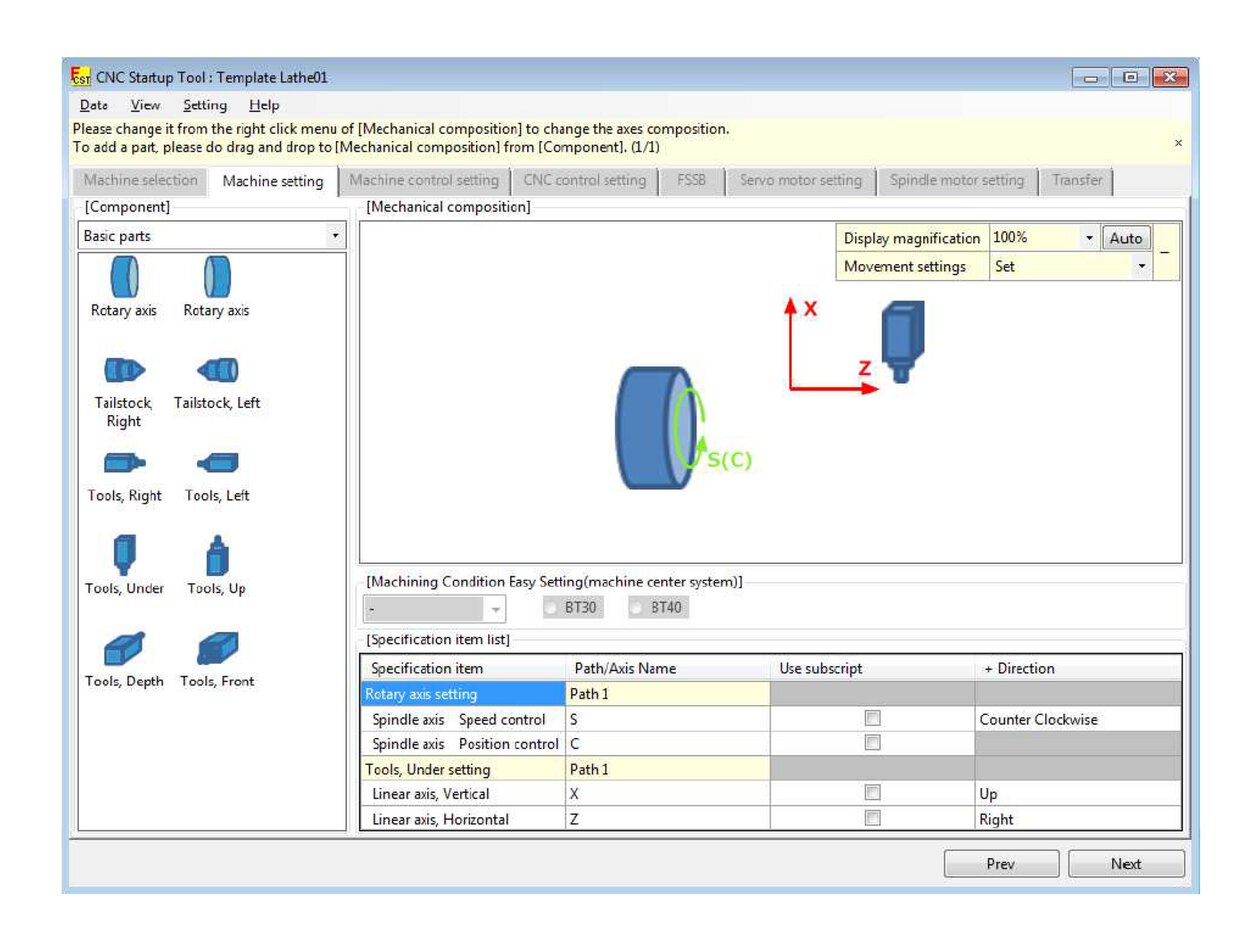

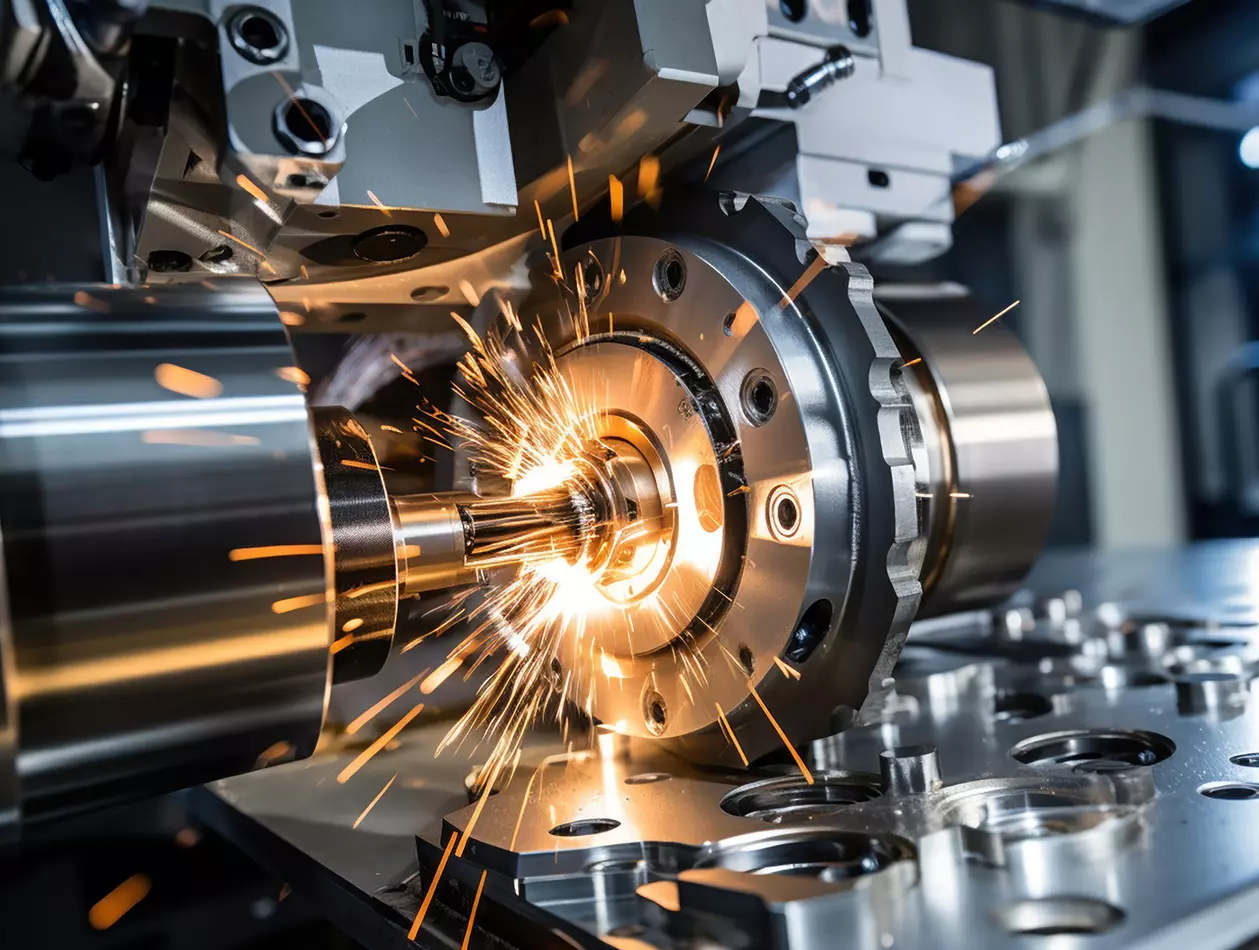

In a world of increasingly complex engineering components, machine tools require ever-more capabilities and functions. The humble lathe, a mainstay of the machining industry, is a case in point. The SMB brand of Türkiye-based Akim Metal today builds lathes with servo-controlled twin turrets, programmable steady rests, live tools, programmable tailstock and integrated automation. To provide optimal process control in the hunt for ever higher component quality, repeatability and productivity, the company takes advantage of FANUC CNC systems.

FANUC Solutions Help Machine Builder Achieve International Success

Most machine builders know that gaining greater market share requires the development of strong supplier relationships based on trust. Turkey-based Dener Group is a case in point, where the adoption of FANUC CNC systems, spindle motors, servo amplifiers and power supply modules has seen the company emerge as a major player in the national and international machine tool market.

Break Up Long Chips with FANUC Servo Learning Oscillation Function

Long chips from machining operations disrupt machine function. ETASIS, a Turkish tool producer, sought a solution. FANUC’s CNC offers the Servo Learning Oscillation Function, which oscillates the tool along the cutting direction, maintaining quality and reducing cleanup. This solution is essential for robotic machine tending and eliminates the need for chip-breaking equipment. ETASIS is highly satisfied with the results.

Perfect Fit for Your Application

CNC Grinding

CNC Turning

Tailored Solutions for Your Industry

Complex Machining for the Aerospace Industry

Complex Machining for the Automotive Industry

Electric Vehicles

Electronics