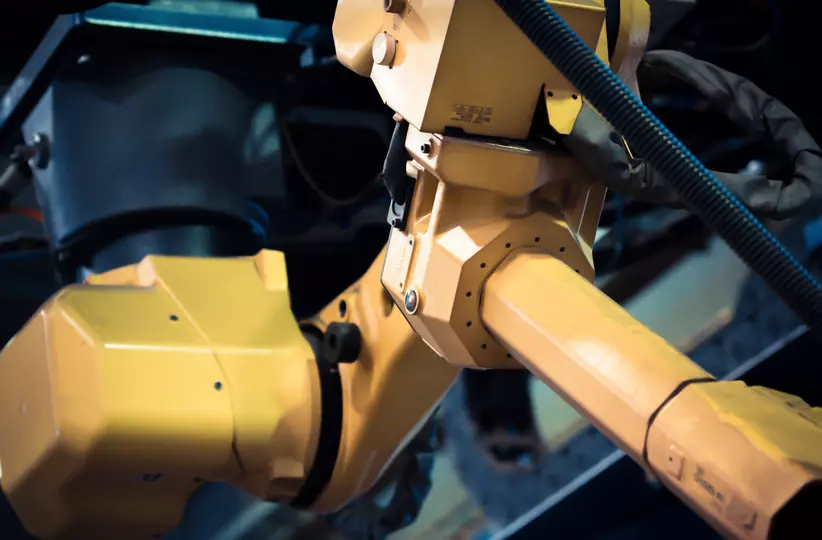

Securely Welded With the FANUC ARC Welding Robot

Get Inspired

Heavy Lifting for Truck Construction

NTM was able to increase the production capacity for its refuse collection vehicles by opting to automate the night shift. By using a heavy-duty robot that can lift up to two tonnes and a robotic welding solution, the company's Finnish plant can now work unmanned at night or on weekends.

FANUC's CRX Cobot Boosts Production Flexibility

Bonvicini Carpenteria today enjoys even higher levels of quality and flexibility. The company can flex between automation solutions whenever production volumes dictate. In particular, Bonvicini Carpenteria is taking advantage of easy and fast robot programming with features such as drag and drop functionality and a simple tablet interface.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Arc Welding