VIGAP

Cake Cutting With Ultrasonic Precision

Bottlenecks in production are often caused by time-consuming manual precision activities. In such cases, an innovative but simple automation step can multiply the production volume.

Share

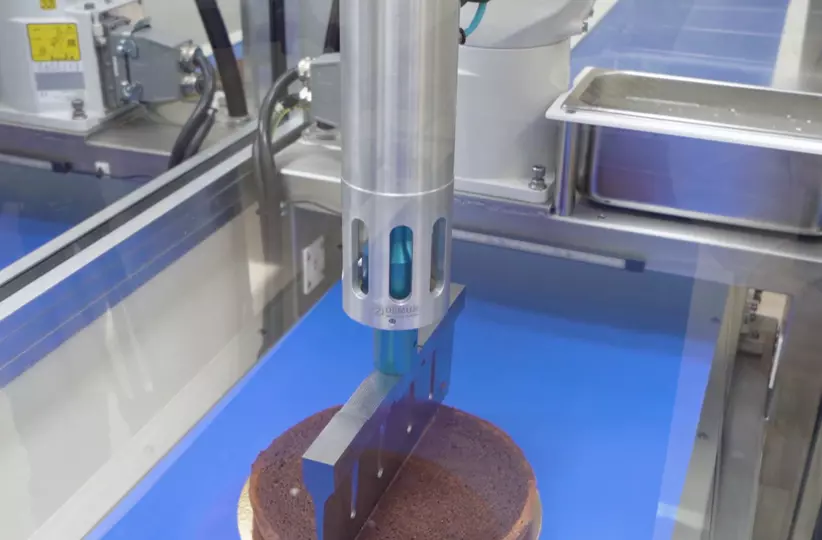

Robot makes the cutting of cakes more precise, clean and efficient.

Cake cutting using ultrasonic technology and a robot arm is precise, clean and efficient.

Machine vision system guides the robot.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Material Handling

Automise material handling with industrial robots to unlock numerous advantages for your business. Significantly enhance efficiency and productivity by reducing the time and effort required for manual handling. Let robots operate continuously without fatigue to ensure consistent performance and minimise errors, leading to higher throughput and faster processing times.

Food & Beverage

Food & beverage is our bread & butter. Contact us today to put our experience in robots in food & beverage industry to work for you.