Medical Device

Matching the Highest Requirements

Whether you are producing parts for implants, surgical devices, or electronic medical equipment, let FANUC CNC systems, robots, and machines help you stay profitable in supplying the medical manufacturing industry. In the growing field of medical devices, from small job shops to multinational companies, manufacturers drive innovation by supplying vital products. Stringent regulations demand high standards for medical equipment, emphasising safety and process consistency in manufacturing. FANUC offers comprehensive solutions for medical device manufacturing. These solutions empower manufacturers to thrive, overcoming challenges and ensuring quality in the competitive medical equipment industry. We are committed to quality, reliability, and repeatability without compromising on the higher standards and more stringent set of regulations typical of the industry. Our tailored solutions prioritise precision and accuracy in the production of crucial medical products.

- Application

- Related products

- Benefits

- Case Studies

Innovative Solutions for Medical Device Manufacturing

FANUC's robotic, automation, and precision engineering technologies are revolutionizing medical device production. From the assembly of drug delivery devices to the complex machining of high-tech medical implants, our solutions ensure maximum quality, reliability, and repeatability. With advanced injection moulding processes, CNC systems, and wire EDM solutions, we handle diverse materials with exceptional accuracy, meeting the stringent requirements of the medical industry. Our commitment to quality assurance, historical traceability, and compliance with hygiene standards guarantees efficient and flawless production every time.

Assembly

Machining Area

Surface Polishing and Sanding

Injection Moulding

Packaging and Marking

Primary packaging, measuring and controlling

Assembly

Robots precisely assemble complex, high-precision medical devices, ensuring highest accuracy and consistent quality, maintaining strict hygiene standards.

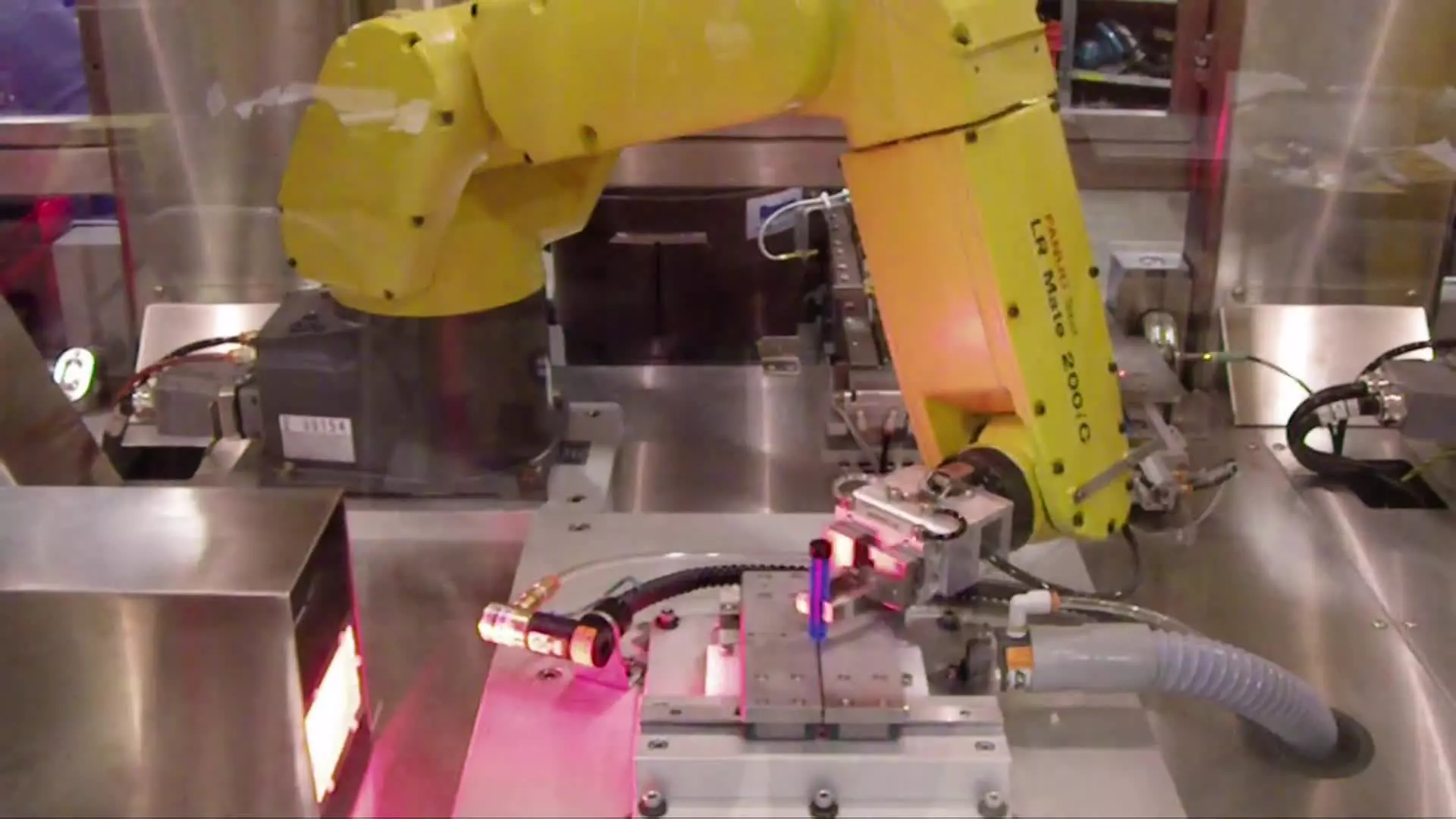

Machining Area

FANUC's advanced CNC systems, ROBODRILL, and wire EDM solutions are crucial for machining high-tech medical devices. Our technologies handle materials like stainless steel, aluminium, and ceramics with exceptional accuracy, producing intricate geometries and high-quality finishes while meeting strict hygiene and clean room standards.

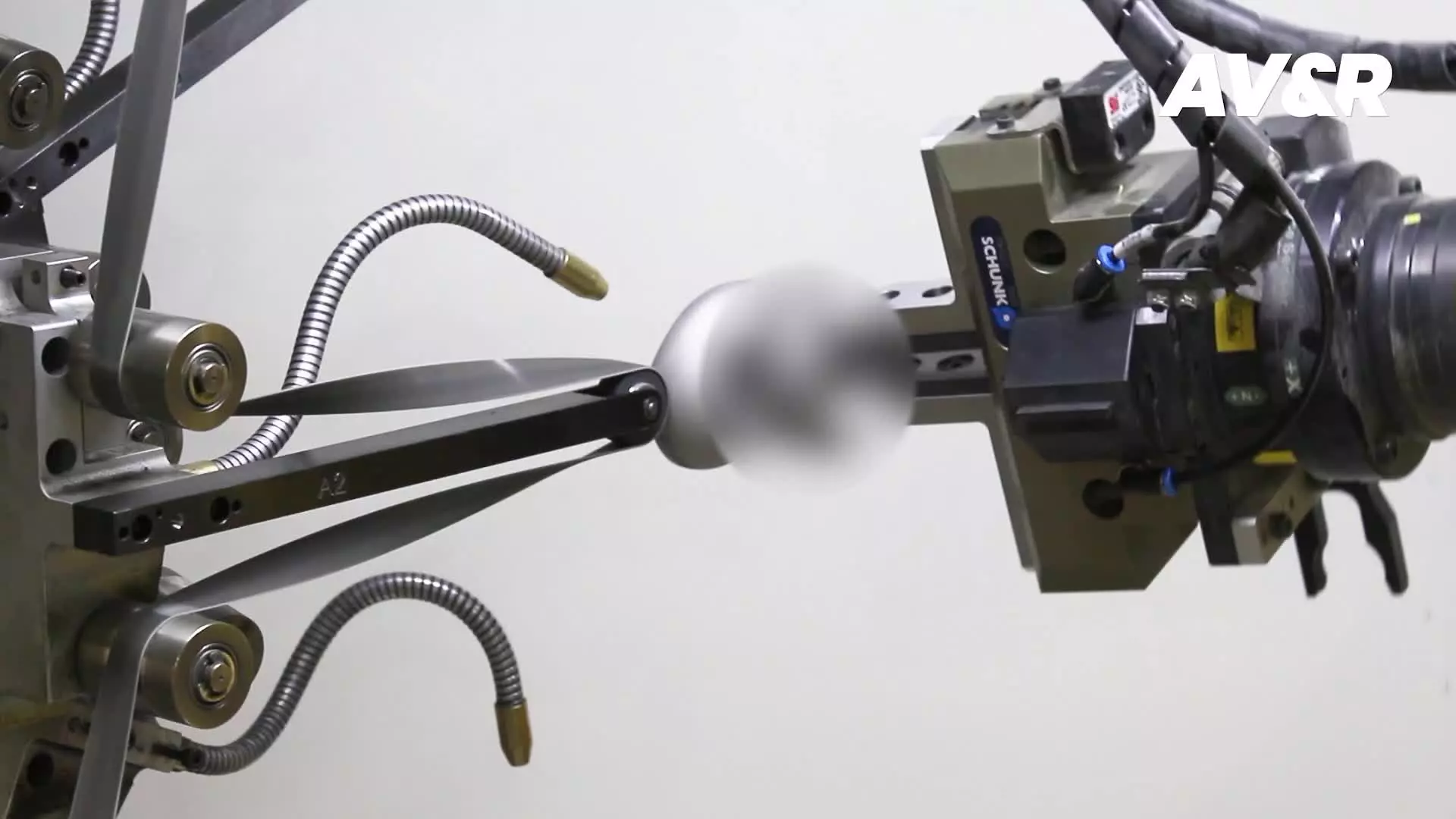

Surface Polishing and Sanding

FANUC provides a variety of suitable robot models for surface treatment applications of medical implants and instruments to debur, polish and sandblast various materials and surfaces with fully integrated FANUC Force Sensors.

Injection Moulding

FANUC ROBOSHOT's precision injection moulding process ensures maximum quality, reliability, and repeatability, eliminating concerns over gas venting or changing viscosity. Our advanced systems, including integrated hot runner control and diverse screw sizes, streamline operations and maintain consistent production efficiency for.

Packaging and Marking

Get your products sorted for delivery with our robots. Automating end-of-line processes, such as wrapping, labelling, packing and palletising, can help to reduce strenuous and repetitive manual labour, often seen in manufacturing medical supplies and devices.

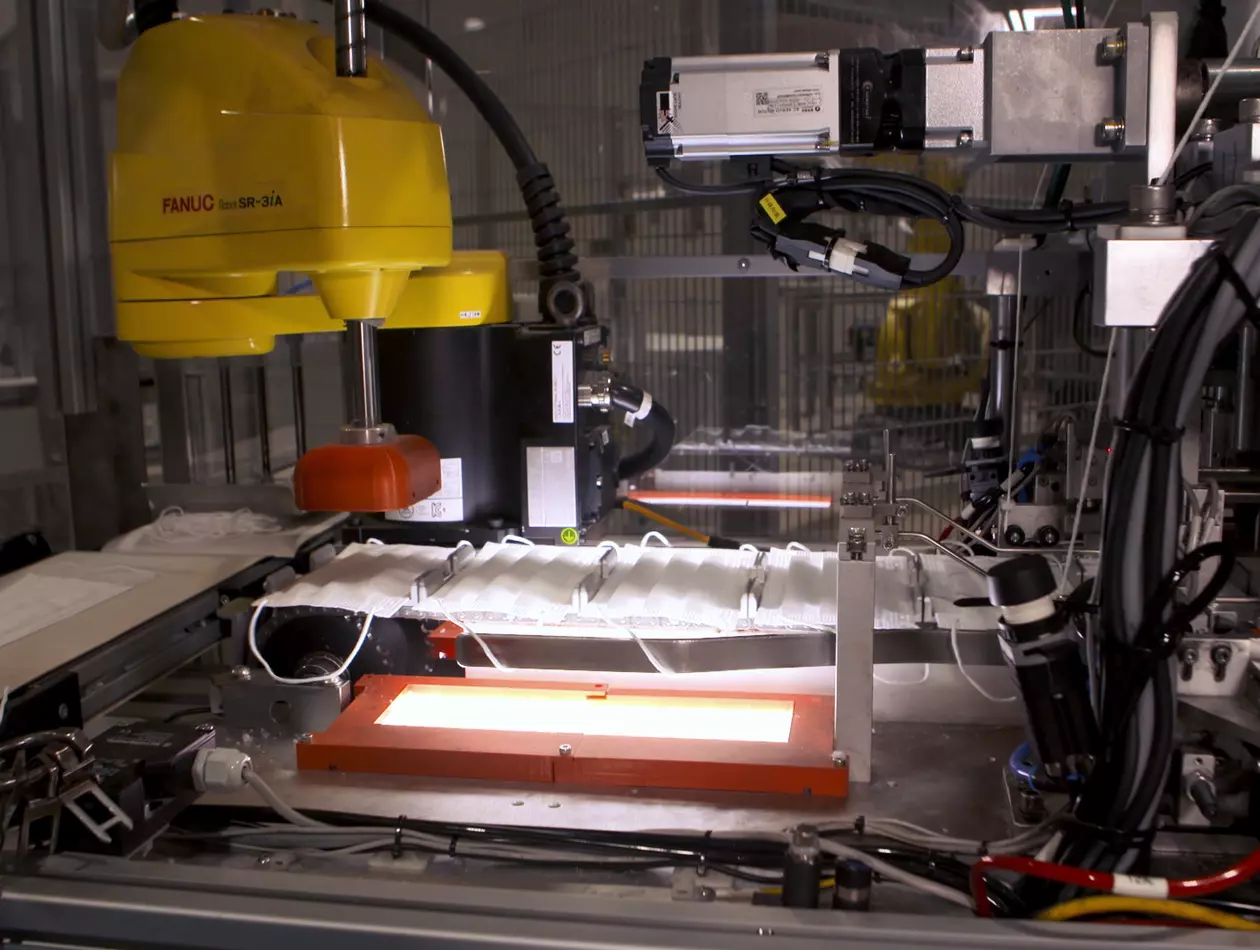

Primary packaging/measuring/controlling

Equipped with 𝑖RVision and 3D Vision Sensor, FANUC robots pick, sort, place and arrange products on a moving conveyor. For example delta robots and SCARA robots are the perfect choice for picking, sorting, inspecting, placing and inserting parts. This can be done at high speed on moving conveyors.

Our Robot Offer

ROBODRILL Compact CNC Machining Centers

ROBOCUT Wire-Cut EDM Machines

ROBOSHOT Electric Injection Moulding Machines

DR-3𝑖B/8L

DR-3𝑖B/6 STAINLESS

SR-3𝑖A/C Food/Clean

SR-6𝑖A/C Food/Clean

LR Mate 200𝑖D/7C Food/Clean

M-20𝑖B/25C Food/Clean

Cleanroom Applications

FANUC cleanroom robots are specifically designed to work in medical device manufacturing.

Built to meet the standard requirements (IP67 standard) of highly demanding lab and medical device environments, they can achieve up to cleanroom ISO Class 5 (in accordance with ISO-Norm 14644), without compromising on robot speed and repeatability.

Highlights

FANUC Collaborative Robots

Vision Inspection

Simulation Software ROBOGUIDE

ZDT (Zero Down Time)

Medical Package

ROBOSHOT Robot Package

LSR Package

Benefits for your Industry

Precision and Accuracy

Consistency in Manufacturing

Improved Quality Control

Efficient Production

Enhanced Safety

FANUC Robots Help Mask Producer Face up to the Challenge

When production demand accelerates dramatically in a short space of time, robots and automation can help meet requirements much faster than many realise. However, this outcome depends heavily on the selection of robots that are easy to install, program and commission.

Automation is the Best Medicine at DEMO

A key player in the pharmaceutical industry, significantly improved its production capabilities with FANUC's automated solutions. By integrating FANUC robots, DEMO optimised the filling, packaging, and labeling processes, resulting in enhanced efficiency, accuracy, and overall productivity in their operations.

A Safe Space for Implant Machining

Machine tending (loading and unloading) is one of the most popular applications for an industrial robot thanks to the elimination of labour costs and higher production throughput. However, in a busy industrial plant, how is it possible to ensure the safety of employees in close proximity to such a fast and powerful installation? The use of FANUC Dual Check Safety technology at world-leading medical technology company Smith+Nephew, demonstrates the optimal solution.

Our Solutions for Other Industries

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.