AUTOMATION HAS A NAME

Smart CNC for Maximum Quality and Maximum Productivity

FANUC CNC provides the answer to demanding machining operations involving multiple axes and multiple path applications. From very small to very large workpieces, from very soft to very hard materials, FANUC CNC provides the ideal balance between utmost precision, flawless surface quality and the shortest possible cycle times. This translates into less non-productive time and eliminates the inaccuracies incurred in multiple-part set-up operations.

The Widest Range of Industrial Robot & Cobots in the World

With more than 100 models, FANUC offers the widest range of industrial robots in the world. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options, straightforward integration, payloads up to 2.3 t and maximum reaches up to 4.7 m.

Compact CNC Machining Centres

The new generation ROBODRILL vertical machining centre promises unrivalled quality and precision at great hourly rates. With an unbeatable tool change time of 0.7 seconds and a turret capable of handling tools weighing 4 kg, the new advanced versions are both the fastest and strongest 5-axis CNC machines on the market. Advanced or standard, every ROBODRILL vertical machining centre is a real high-speed all-rounder offering incredible performance and unbeatable efficiency.

Electric Injection Moulding Machines

FANUC ROBOSHOT takes state-of-the-art CNC precision technology from turning and milling and applies it to electric injection moulding. The results are greater acceleration, ultimate precision of movement and extremely short cycle times to produce large quantities of consistently high-quality parts.

Wire-Cut EDM Machines

Where wire EDM is concerned, accuracy has traditionally come at the cost of speed. That’s why FANUC has developed a next generation ROBOCUT wire-cutting machine. The α-C𝑖C series comprises versatile all-rounders. With incredibly long mean times between failures, low maintenance, longevity and excellent uptimes, these future-proof spark erosion machines are designed to save time and drive down unit costs while ensuring superlative accuracy and cutting efficiency.

Looking to move your productivity to the next level?

FANUC brings together automation with advanced analytics to drive smarter, faster business decisions for industrial companies, regardless of their size. Discover scalable IIoT products that increase manufacturing efficiency through better production quality, performance, uptime and OEE. Make your production processes more efficient thanks to our IIoT solutions.

FANUC Plans

Our service Plans are built to ensure optimal machine uptime, consistent output quality, and long-term operational efficiency. All with predictable costs and tailored support. Whatever your product and your need, there is the right FANUC Plan for you!

Enhance Your Operational Efficiency

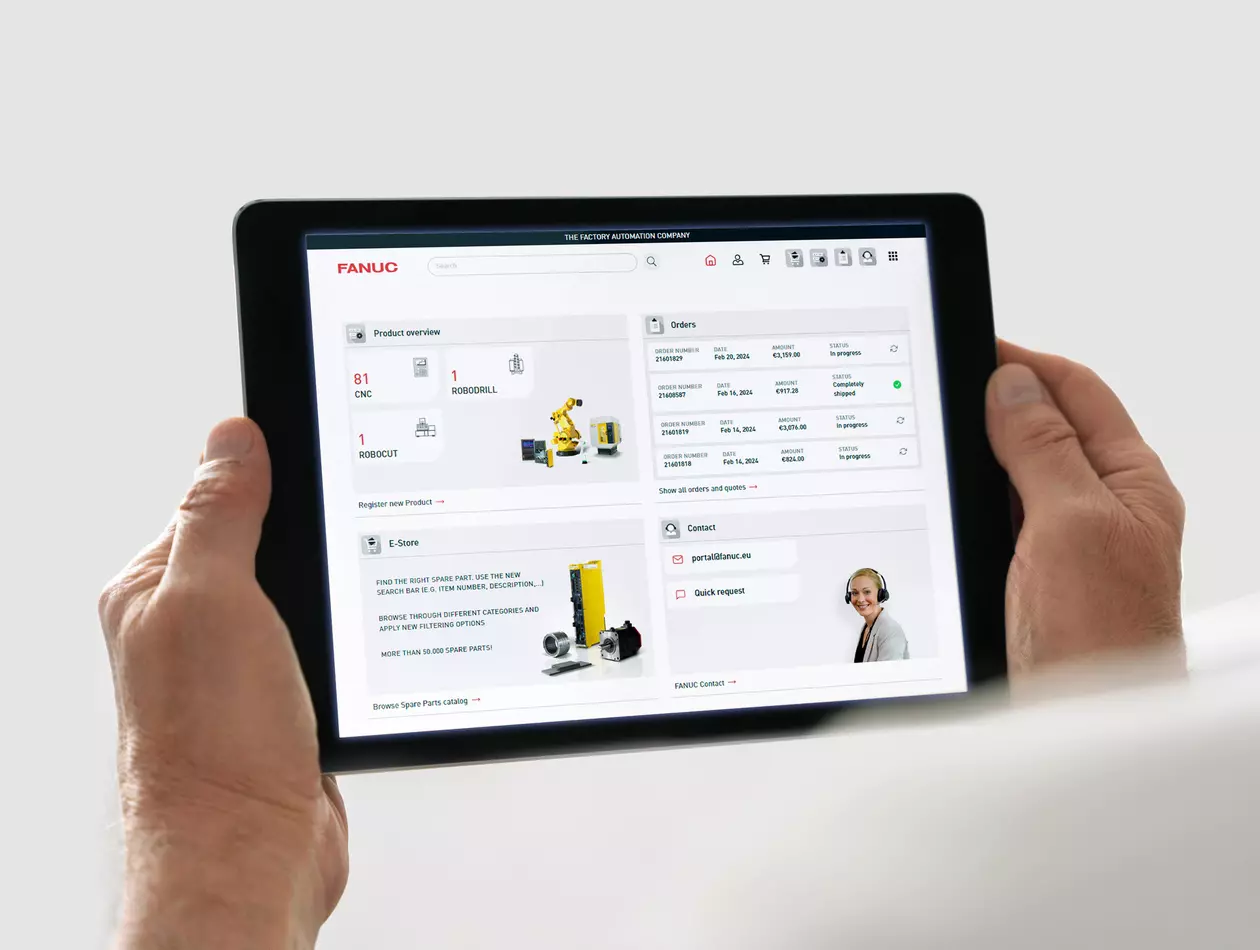

Discover MyFANUC - FANUC digital service platform to simplify your business:

E-StoreDownload center Product registration and overviewOrders & Quotes

Find out how our Customers Grow together with FANUC

Explore our various case studies, covering a wide range of automation solutions for small and large manufacturers operating in all kinds of industries around the world.

FANUC Among Clarivate’s Top 100 Innovators

FANUC CORPORATION has been recognized as one of the “Top 100 Global Innovators 2026” by Clarivate, highlighting its continued leadership in industrial automation and innovation.

Your Global Partner in Factory Automation

When partnering with FANUC, you get access to a global network of automation experts who are ready to help you take your manufacturing operations to the next level. We are present in more than 105 countries, covering over 250 locations worldwide. The strong local presence lets you easily get in contact with a local FANUC office near you — because we know the important value of being able to meet face-to-face when considering integrating automation into your manufacturing process.

Get Lifetime Support for your FANUC Products

Automation solutions are often a considerable investment for your business, and as such, you want to maximise their value throughout their entire lifecycle. At FANUC, we put service first and offer flexible service and support for all FANUC products — whenever and wherever you need it, 24/7.

Our Commitment to Build a more Sustainable Future

At FANUC, we are deeply committed to sustainability, integrating environmental protection into our automation solutions. Our manufacturing technologies prioritise responsible machine operations, aiming to reduce energy consumption, promote waste reduction and minimise environmental impact. With accolades and partnerships in nature conservation, we strive for continuous improvement in environmental credentials worldwide.

FANUC Among Clarivate’s Top 100 Innovators

FANUC CORPORATION has been recognized as one of the “Top 100 Global Innovators 2026” by Clarivate, highlighting its continued leadership in industrial automation and innovation.

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.

Boost Efficiency, Precision, and Productivity with FANUC's Solutions for Different Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.

Become an Expert in Factory Automation

FANUC Academy

Solutions for Education

Worldskills & Young Talents

Shape your Future with FANUC

Join the FANUC Team! Explore exciting career opportunities and be part of a global leader in factory automation. Discover your potential with FANUC today!

News and Events

News

Get the latest updates from FANUC! Read our latest news and press releases to learn about our innovations and industry insights.

Events

Join us to explore the latest in automation and robotics. Our events feature FANUC products, live demos and networking opportunities. We look forward to seeing you!

FANUC Newsletter

Don't miss any news and always stay up-to-date with our FANUC newsletter. All you have to do is register here. We hope you enjoy our FANUC News!